You know what ? It’s time to thin the edge of Gambit.

Pictures are better than thousand words.

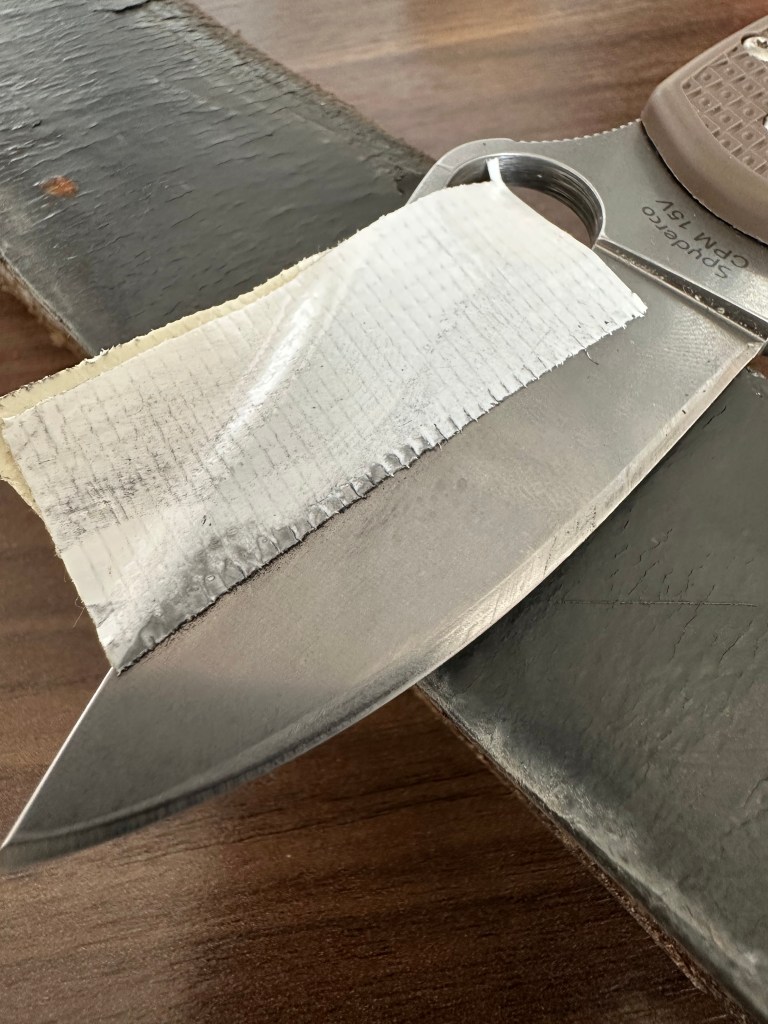

The gaffer is here to protect the blade against my clumsiness.

The Double Stuff 2 is the main tool. But it is old now.

It has lost some of its teeth in many many edges reprofiling…

But eventually it is a cheap Sharpy bought on Amazon which seems to be 15V best friend. It is 800 grit.

And it bites into 15V like no tomorrow.

So I was able to round the edge’s shoulder. Let’s test it.

It goes deep and steady.

There is real improvement. But gosh, 15V do not like to lose its particules. Compared to Magnacut or SPY27, CPM-15V is hellish.

Now I perhaps don’t have the best diamond tools for that.

But really, it is not a piece of cake in my book.

Now could it be a answer: The Military 2 reaching the 67 HRC ?

But that was exactly my impression after watching the YouTuber’s video — until Jake, a metallurgist for 14 years, left an exceptionally detailed, well-sourced comment under this review.

To quote his conclusion:

“… Spyderco did an amazing job getting a near custom level heat treatment on an amazing steel at an affordable price to many people who otherwise wouldn’t have been able to spend large sums of money on customs. But expecting 67Rc is a bit too much. Shawn has said it repeatedly that it isn’t realistic for a production knife company to hit hardness levels that high and also be able to work the material.“

Many thanks to Jake for his eye-opening comment — truly appreciated!