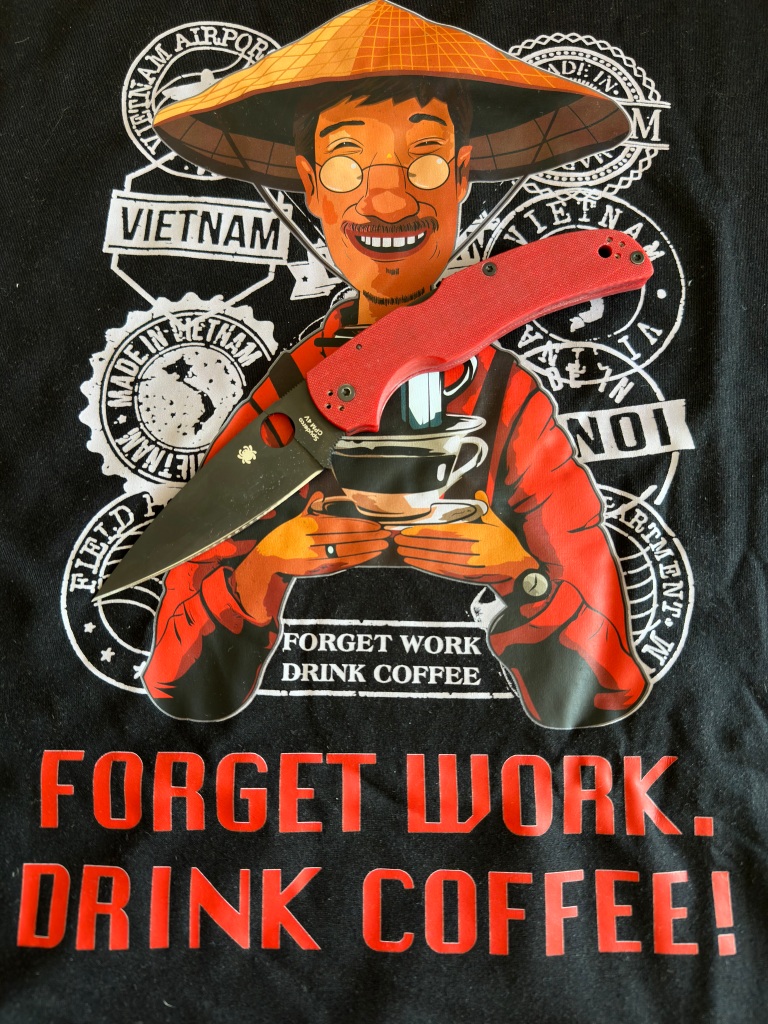

This is the C229RWDP Spyderco Shaman in CPM-REX 45 Satin Plain Blade, Rosewood Dymondwood Handles and it is a KnifeCenter Exclusive.

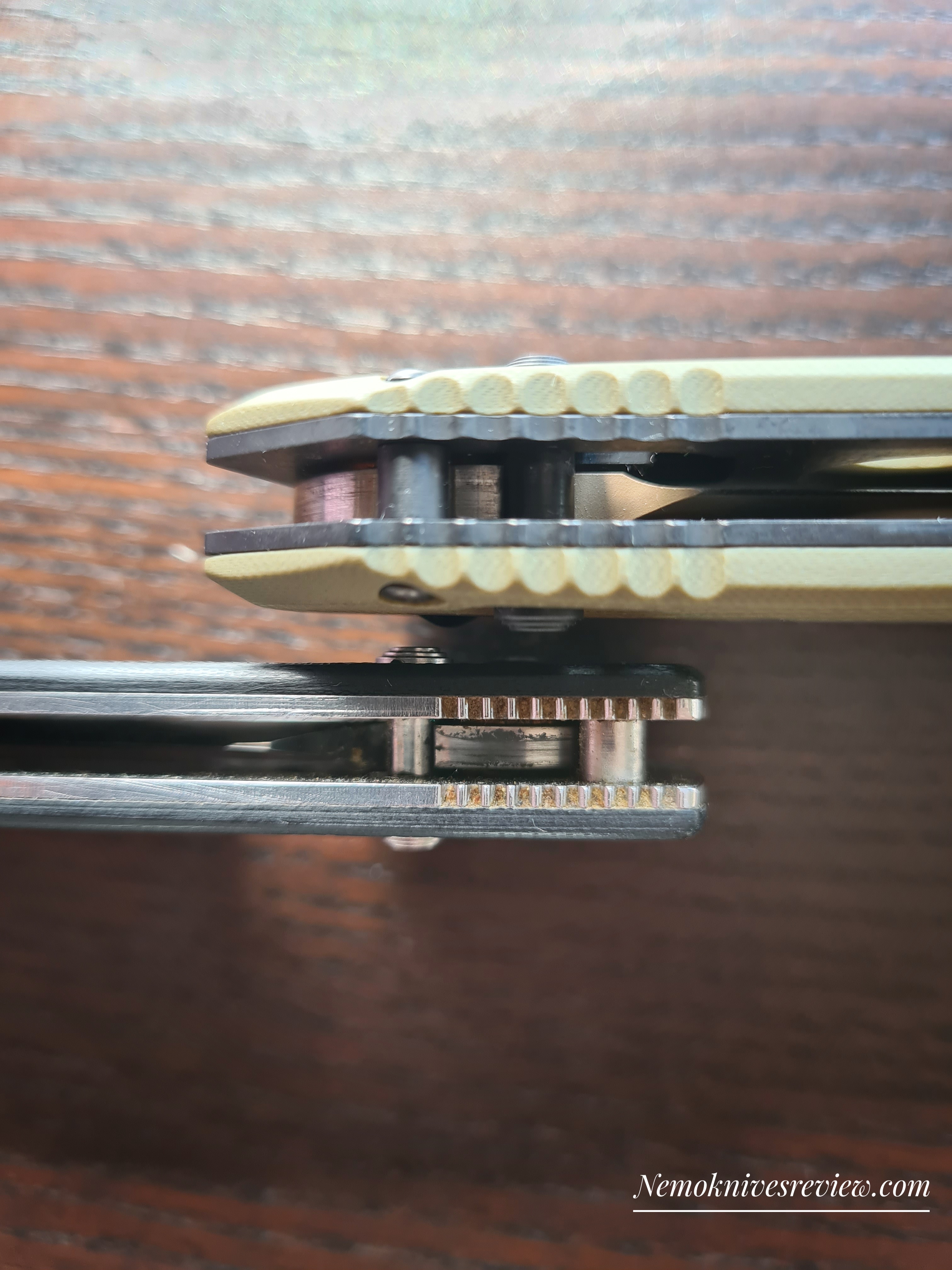

Like the previous Crucarta, Micarta Cruwear Shaman, this is a very rare animal and a king in his family. Of course they are discontinued too. You can notice my Crucarta has now convexed edge where the Tree-Rex is still wearing her factory edge.

There is also another difference you can notice: the pivot screw !

The handle of the Shaman is appealing for beautiful textured handle. Micarta is such a pleasure but faux wood like this Dymondwood is also a pure pleasure under the thumb.

I have been able to see a broken pakkawood endura handle so what is Dymondwood ?

“”Dymondwood” is the tradename for a product that was produced by Rutland Plywood. Essentially, it is a lamination of very thin veneers, usually birch, impregnated with a resin. The designation Walnut, Cocobolo, etc refers to the color of stain used, not the species of wood. It is a very stable product. Unfortunately, the Rutland factory was destroyed by fire about a year ago. As a result, the future supply of Dymondwood is in doubt.” dixit Bertl on the Bladeforums. This one is rosewood Dymonwood and it looks like real wood to me in rich brown colors and not as orange as the pictures. So it is an excellent surprised. This is the pleasant feel you can get from a rifle, it is warm and pleasant to the eye. “Generally the terms Rosewood, Cocobola, Heritage Walnut, Cherrywood etc are dye colors, not wood species.” said another forumite on the same page.

The factory edge is even and really really sharp. Just some pass on leather and I got a clean razor which cut the hairs without scrubbing the skin. It is amazing.

So I have decided to round the edge of the spine but keep the edge as it is for a change.

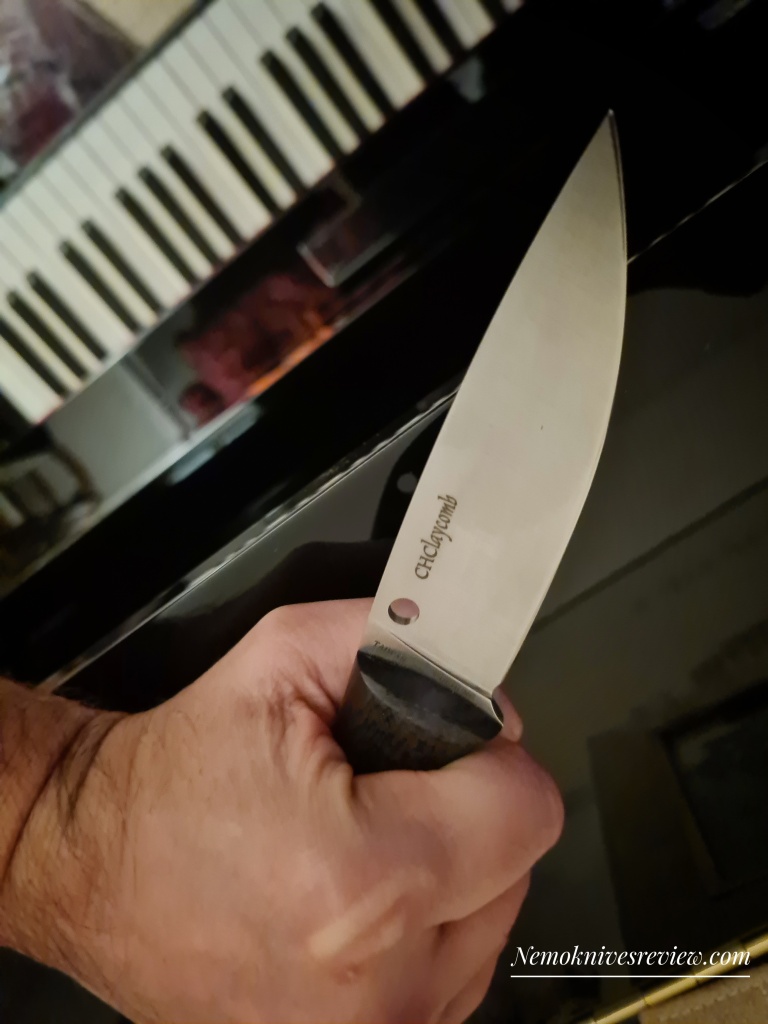

CPM REX 45 is a new steel to me. According to crucible: “CPM REX 45 is an 8% cobalt super high speed steel which has excellent hot hardness along with good wear resistance and toughness, making it suitable for difficult machining applications.” A data sheet.

“It has red hardness comparable to that of M42 but offers abrasion resistance even better than that of M3. With its excellent red hardness, good wear resistance and good toughness, CPM Rex 45 is suitable for high cutting speed applications.”

Carbon 1.30%

Chromium 4.05%

Vanadium 3.05%

Tungsten 6.25%

Molybdenum 5.00%

Cobalt 8.00%

Sulfur 0.06 (0.22%)

As far as I understand a sprint run with orange G-10 and the same blade will be available soon and lot of REX45 knives are coming.

On the Spyderco Forums you can find a great test of that steel by Deadboxhero comparing REX45 and CPM M4.

Eventually he found M4 works great with coarse edge and REX45 with polish edge. That what I was looking for as polishing edges is my guilty pleasure.

“So far, I’d say people will enjoy the properties of Rex 45, while M4 prefers a more toothy finish Rex 45 will prefer the opposite which is unique amongst Crucible steels let alone US steels. It’s interesting to a US steel closer to the properties of a japanese steel which have more of a bias toward Polished edges.” wrote Deadboxhero.

REX45 seems to be the same as HAP40 found in the Endura review, but HAP40 was 63HRC when REX45 heat treated by Spyderco is pushing the envelop to an incredible 66-67 HRC as hard as this Japanese ZDP189 Rockstead Higo… For the record the Maxamet blades are at 70HRC and brittle as ceramic in my record.

Also the 4% chrome makes it a staining steel and I expect to find a patina after to use.

My friend Max Wedges has given me that advice about cobalt:

“Careful with the knives you use with food (specially acid food). The problem is that COBALT is a Cancer agent. For any steels that are sharpened often & go close to food, I avoid ALL Cobalt steels (Tungsten Carbides are less of an issue). If you sharpen you always get some “swarf” residue on the blade… better clean it properly before use: use a cotton swipe with alcohol & a drop of tea tree oil, after carefully washing & drying the blade (& avoid the grinding dust like the Pest it is). M4, M2 Steels have no Cobalt. CPM S110V, N-690, VG-10 do, so I use the older S90V, S35VN, RWL-34/CPM154, 440-C or AEB-L for food knives. Were I a knife maker, I would totally refuse the use of any steels containing Co. Moly is related to Tungsten: these are much less harmful, and are bound into Carbides… but Cobalt forms no carbides & gets airborne easier. Be wise?”

That’s very interesting ! It is something to discuss.

How a steel could harm your health is a subject which I have not seen yet on forums.

Steel is not neutral. If you cut a green salad with carbon steel, the leaf will get brownish. The same cuts with a stainless steel and the salad will stay green for hours. Steels are not neutral with the medium they cut. Is a Powder Tech steel using 8% of Cobalt be poisonous ?

“However, if you sharpen a knife, you are grinding the steel with an abrasive. Even a slightly abrasive chef’s “steel” (a rod used to sharpen and condition chef’s knives before using) will leave a residue of the blade steel and the abrasive (silicon carbide, ceramic, aluminum oxide, other steels, etc.) behind. This residue is called swarf. How many chefs have you seen whip a knife blade on a rod, then go right to cutting your brisket? How many wipe the swarf onto a grimy rag that hangs over their shoulder or around their belt before cutting your salmon? How many actually go to a sink and wash the knife with soap and water before returning to the block or cutting board?”

From The Special Case of Cobalt by Jay Fisher provided by Max Wedges.

“Guys who purport to be experts—posting particularly on knife forums—claim that concern about cobalt is all amped-up hype. It’s easy to find endless discussions, particularly about VG-10, and the concern about exposure to cobalt. The uneducated flock to these forums; they are not experts, they do not read scientific studies, they do not believe the CDC, the American Cancer Society, or any of the numerous organizations that warn against cobalt exposure. “Show me the reports,” they say, yet they are unable to find the very references that the rest of us can easily locate. The reports are numerous; the professionals don’t just make this stuff up, but you have to read.

They claim that you would have to grind up and eat knife after knife in order to be exposed to enough cobalt to cause cancer. They know this because they are toxicologists (ahem), and know that metal exposure recommendations are a conspiracy by nut jobs (uh-huh). I guess all the nut jobs work for the CDC and the American Cancer Society… right?

They sometimes go on to compare cobalt to chromium, vanadium, and other alloy elements, saying that they are just as dangerous. This is typical ignorance on forums. All of these elements have been extensively studied, and cobalt has been found to cause cancers, while the others have not. This is the reason I state over and over, “Don’t get your information on a forum of any kind!”

Experts, professionals, and scientists don’t post there; open forums are mainly occupied by the uneducated and unknowledgeable anonymous masses, hobbyists, and part-time knifemakers and enthusiasts who know very little about knives overall. If you believe them, then you’ll believe that the best steels are hammered together in an open fire, just like it was done in 1875. You’ll believe that the entire modern metals and machining industry does not know anything, that some oaf with a hammer can make an improved axle, planer blade, or turbine part. After all, you saw it on the History channel…

Sorry to be so blunt, but if you are reading this, you deserve to know the truth. Or maybe the thousands of professionals at the CDC, IARC, NCS, NIOSH, and in the research community are all wearing tin foil hats… sigh. Welcome to the internet, where the idiots get the same voice as the intelligent, damn the truth!”

So guess what ? In my great wisdom (ahem) I have asked the question on the Spyderco forum 😀

Knowing Japanese Chef knives are often HAP40 and VG10. Even my Ikea Chef Knife is VG10… Let see what they think about Cobalt in steels:

https://forum.spyderco.com/viewtopic.php?f=2&t=85929

Even Pekka helped there:

Me: Do you think Cobalt dust could be dangerous ?

Pekka: Every dust is ! I do not believe that anybody get cancer if they sharp knife sometimes of month… if they do not collect all dust for they sandwich  There is lot of f.ex. nickel in steels and chromium etc. all are very bad for health.

There is lot of f.ex. nickel in steels and chromium etc. all are very bad for health.

Me: How do you protect yourself?

Pekka: I do not breathe  serious I use mask with motor. But no gloves, I do not like gloves, I lost my feeling, as you know I do everything with freehand method, no jig etc.

serious I use mask with motor. But no gloves, I do not like gloves, I lost my feeling, as you know I do everything with freehand method, no jig etc.

So eventually we can eat with our knives but not eat our knives…

And also Sal Glesser which was one of the rarest bringing zero assumption or opinion but facts.

Most of the other comments were just mostly about bragging on other way to die like:

“Compared to driving in city traffic, I would say the danger from cobalt or anything in your knife is truly negligible.”

“I would assume it’s perfectly safe when bound together with iron.”

“The oxygen your breathing right now is also causing oxidative stress and damaging your cells and DNA with free radicals. Yet, we keep breathing.”

“Life has a 100% chance of death, get over it.”

“There is cobalt in your food and organs. It’s essential to live. Got B12?”

Yes, being deficient in vitamin B-12 causes physical and psychological symptoms, including nerve problems, fatigue, and difficulty thinking…

And yes we got so many chemicals in our bodies but it’s a matter to have them in the right proportion in the right place.

Oh well…

Fortunately Sal Glesser saved the day:

“Fun subject. Figures it would be Nemo to bring this up from the depths.

I remember Nemo and I discussing Eric Taberly’s death in the sea, because he spent so much time at sea. So in the end, what gets you is what you do the most? That concept brings up some interesting thoughts?

We have to put warning labels on our products because they might be sold in California and there is sever punishment for not warning the people about the danger of the chemicals in our products.

In Manufacturing, most grinders and mills are used wet. Masks re a good idea if dry grinding. I breathed in a tiny amount of G-10 dust once and it did make me sick.

sal”

I guess we were the only few there to see that thread as a “fun” subject as there is the new cartesian way to answer questions of the Internet:

Someone even has written:

“As Sal said, what gets you is what you do the most. Now that is actually worth thinking about.”

Hummm, I guess many forums specialists will eventually die from masturbation as their armchairs are mostly harmless to their health… No reason to be afraid from any poisons, then.

And Sal final word on that subject:

OK, so back to this wonder of a knife: I have changed the position of the clip to a tip down carry because I have found that the Spyderdrop openings are really easy and fun on the shaman. The steel backspacer give momentum and the compression lock is a breeze to operate.

This knife got zero lateral play too. It can really be open as fast as the good old Millie. For the record 25 years ago Sal’s was beating in speed every owner of automatic knives while opening his own Military. Spyderdrops are really an advantage in putting your tool in action very fast. Also the fact the clip is not a deep carry clip makes the spyderdrop a breeze to execute. Actually it is fun with the Shaman !

As illustrated: the clip is not deep carry but, oh well it is a big knife which rides small in the pocket.

Trying the edge on some hard chestnut wood and the cuts are deep and steady. It will be a pleasure to use ! It also bring the same smoothness I have had enjoyed on M2 High Speed Steel found on Benchmade knives back in 90’s. Once cut the wood chip feels smooth under the thumb.

A funny thing has happen to my parcel when flying from the Knifecenter to Paris: it has gone West instead of East and has landed in Hawaï, Honolulu ! Thank to Kristin at the Knifecenter it has been rescued and after one week of storage in Hawaï has been able to fly from the other side of the planet and land to mailbox in 48 hours.

For the record, Hawai as the place where Jurassic Park has been filmed. It was logical for my Tree Rex to go there first. 😉