If you were around in the 1990s, you remember the Steel Wars.

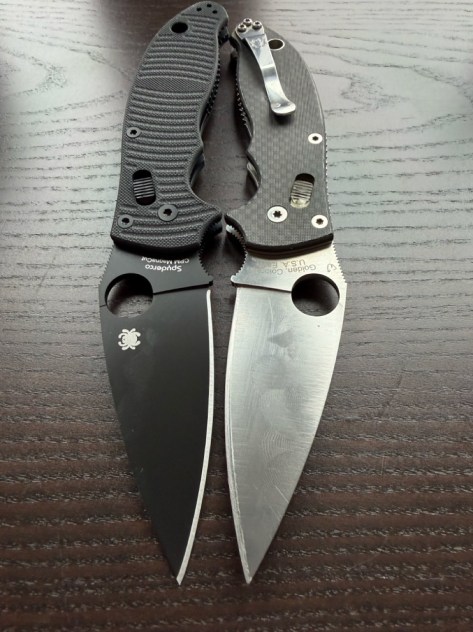

Back then, the aspirational trio was ATS-34, 440C, and D2.

ATS-34 wasthe working man’s stainless . 440C was the gentleman’s stainless . D2 was the semi-stainless tool steel brute with some bite.

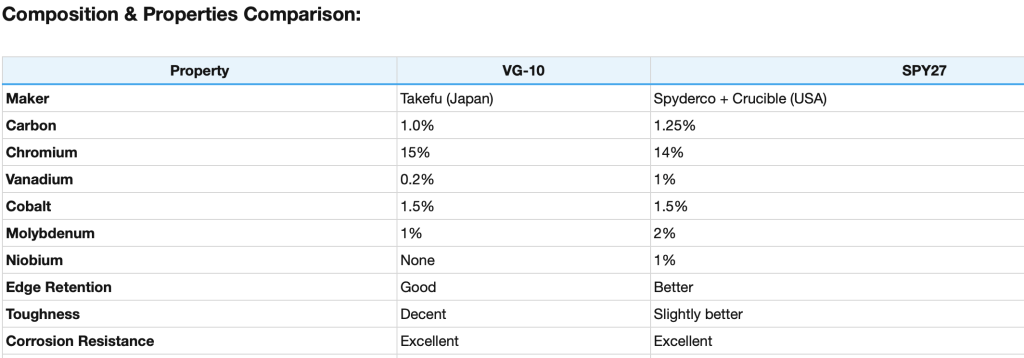

Users were happy with Gin-1 blade. VG10 was not yet available. Hard chore fixed blades were made in 1095 or 1075 or 52100 carbon steel.

Anyway, those were the benchmark steels — the ceiling, not the starting point.

Then something shifted.

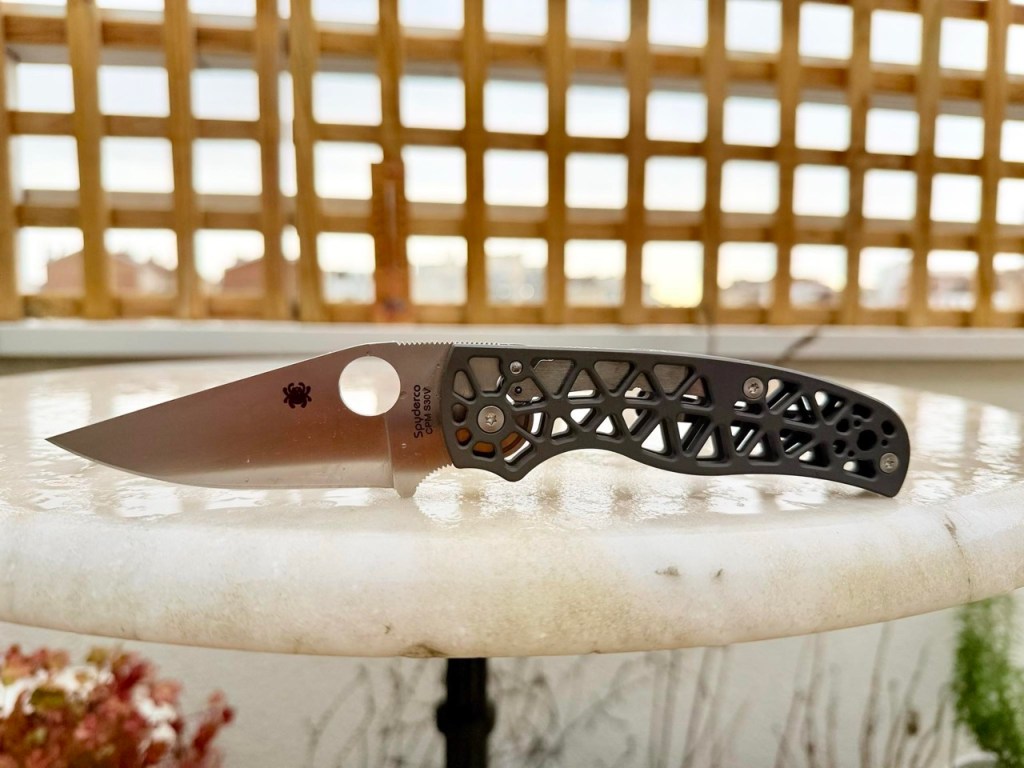

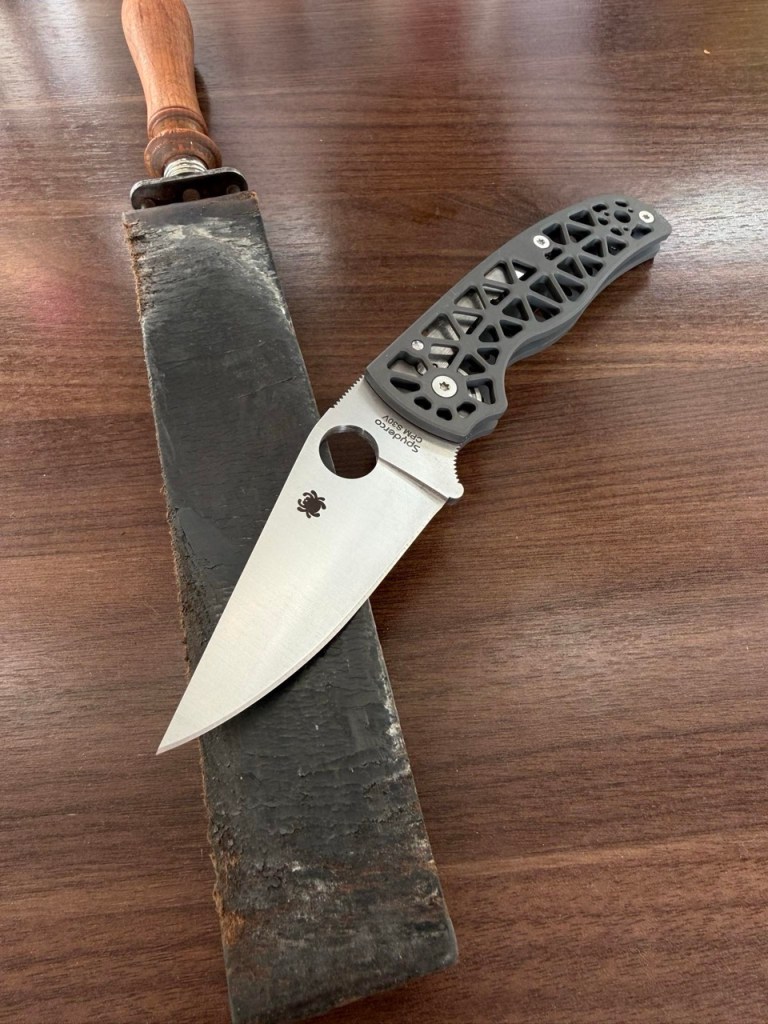

In 1996, Spyderco did something quietly radical with the original Spyderco Military: they moved from ATS-34 to CPM 440V — later renamed S60V. It wasn’t just a steel swap. It was a philosophical statement.

The Military became the first production folder to embrace Crucible’s Particle Metallurgy steel.

That moment matters a lot for knives users and for Spyderco.

It marked the beginning of the modern steel era in production folders — high vanadium content, fine carbide distribution, wear resistance that outpaced what most users even knew how to sharpen. It was controversial. It was ambitious. It was forward-looking. Typical Sal Glesser’s route to unknown territory.

And the Military has been evolving ever since.

Disclaimer: This knife has been provided through Spyderco’s Ambassador Program, upon their own request. Thank you to the Spyderpeople for letting me review it and enjoy it.

Enter the Military 2 Salt: Bright, Bold, Unapologetic — yellow and black handle, corrosion-proof attitude, purpose-built for brutal environments.

The Salt line has always been about defiance — defiance of rust, of humidity, of saltwater indifference. But this is not just a “marine” variant. It’s a continuation of a lineage that has consistently served as Spyderco’s testbed for what’s next.

From ATS-34…

To CPM 440V…

To S30V, S90V, S110V…

To the modern exotics.

The Military platform doesn’t chase trends. It previews them.

Fast forward to Gambit my CPM15V “Mother of All Bears” sprint run — a steel with outrageous vanadium content and edge retention that borders on absurd. In many ways, that sprint heat treated by Shawn Houston wasn’t just a collector’s piece. It was a thesis statement.

It said:

The Military platform still exists to push metallurgy forward.

Fifteen percent vanadium. Let that sink in. In the ‘90s, we thought 440C was peak sophistication.

For the record Rambo II Knife was made from 440C.

If the 1996 jump to CPM 440V (some kind of powder steel version of 440C) signaled the start of the particle steel era, then the inevitable future feels clear.

At some point — whether as a sprint or full production — the Military will wear CPM MagnaCut. A steel you can bring to the rain forest where even camera lenses can be eaten by fungi.

And when Spyderco does a Salt, it’s no gimmick. It is the logical next step.

From a certain point of view, MagnaCut represents what ATS-34 once was supposed to be (Chris Reeve’s Sebenza were made of ATS-34) — stainless performance without compromise. Fine carbide structure. Balanced toughness. Real corrosion resistance. Practical edge stability.

As the Military began its journey by embracing the future of steel before the market demanded it, a MagnaCut Military is simply continuing that tradition.

The Military isn’t just another large folder.

It’s a timeline. A flagship. A knife Sal was giving for Eric for his military service.

But also it reflects where the industry was, where it is, and where it’s going.

That beautifully “wasped” Military 2 Salt — with its unapologetic yellow and black scales — stands as a modern chapter in that story: corrosion-proof, high-performance, and unafraid of specialized steels.

For those of us who remember when ATS-34 felt exotic, holding a Military 2 Salt today is a reminder of just how far production knives have come.

And if history is any guide, this won’t be the final evolution.

It never is……. Magnamax ?

Anyway, Magnacut is a wonderful tough steel

There is, however, one issue with the Spyderco Military 2 Salt — and it’s not the steel, the ergonomy or the lock which came with zero lock stick BTW.

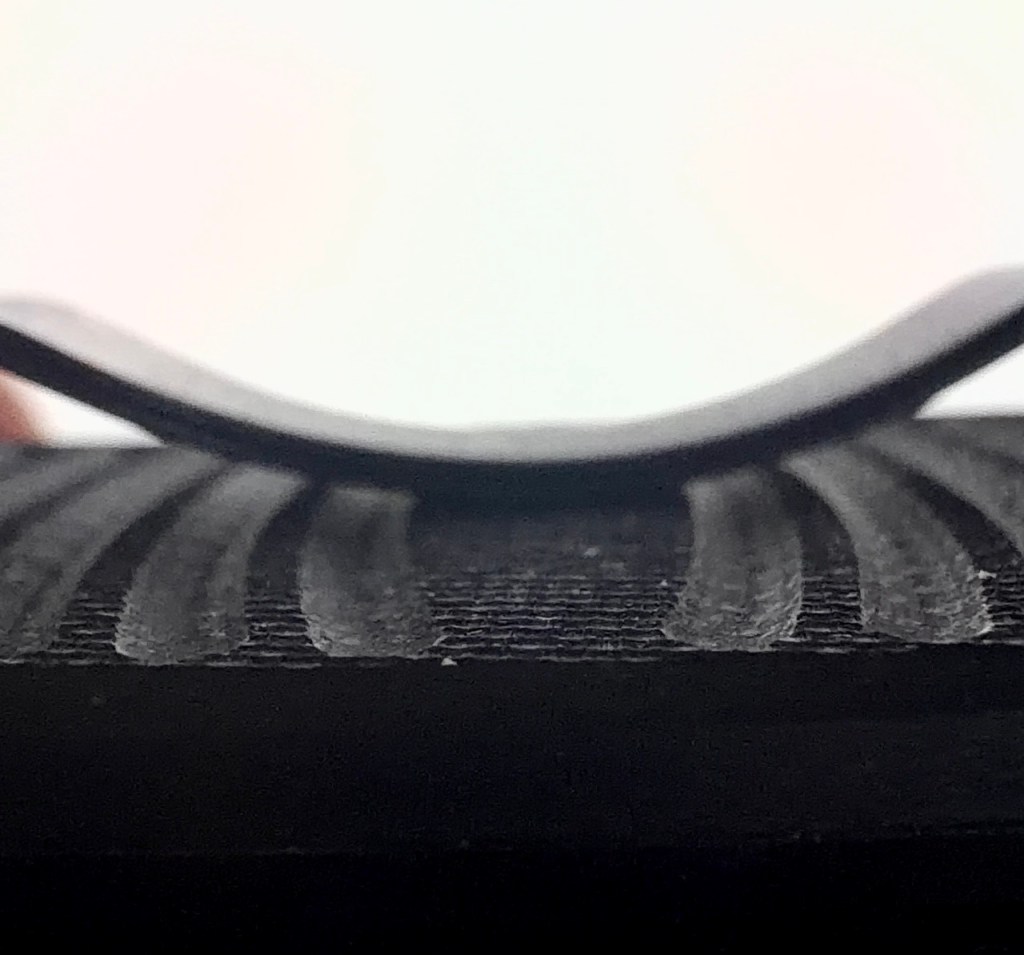

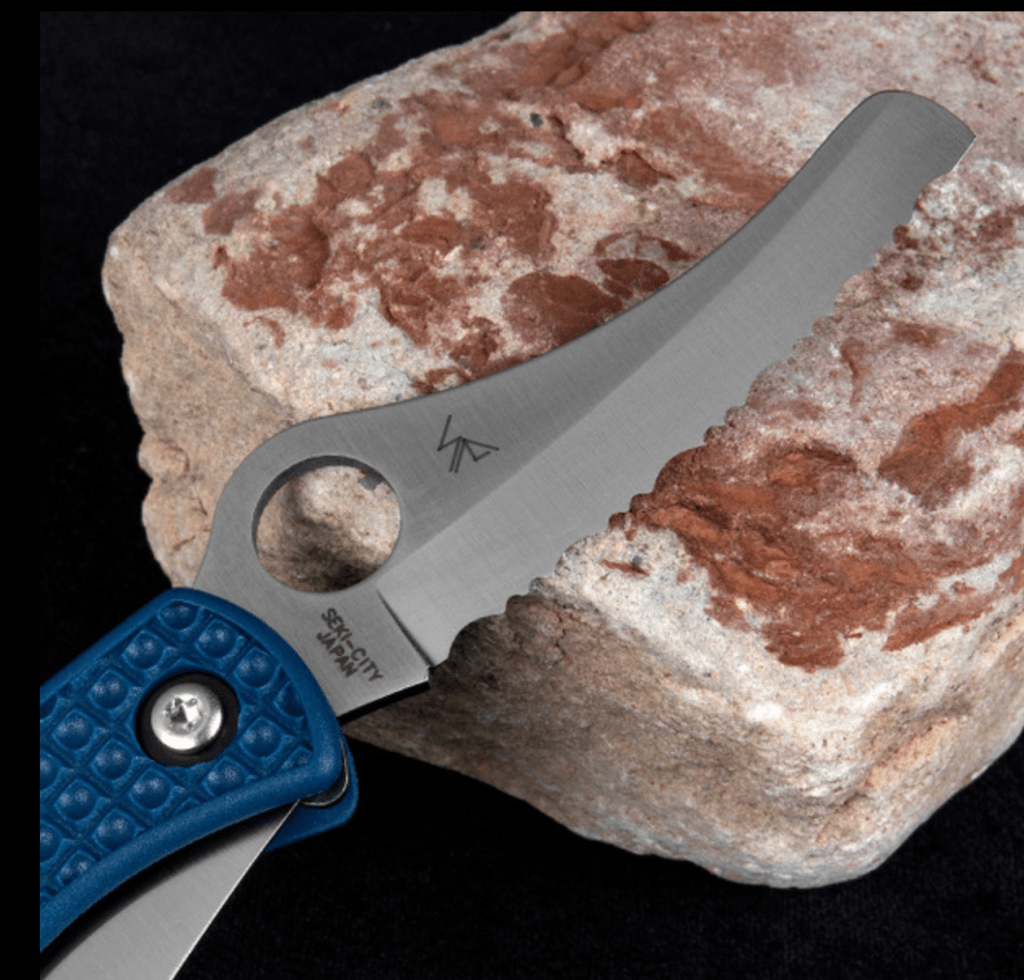

It’s the clip placement. As you can see no clip can reach that central flat spot. It stays on the grooves !

“The meticulously machined Caribbean Bi-Directional Texture pattern not only ensures a secure, non-slip grip, but also reveals the scales’ alternating black and yellow layers to enhance the knife’s visibility in and around the water.”

Yes but that yellow/black Salt version retains the aggressive, highly contoured handle geometry that makes the Spyderco Caribbean such a secure tools in wet environment.

“The Caribbean’s blade is housed in a vibrantly colored handle featuring scales crafted from layered black and yellow G-10. Their intricately machined pattern provides a non-slip texture and reveals the contrasting colors to create a high-visibility striped design. “

Those scales are not flat which is “handy” especially in wet or gloved conditions. From a grip standpoint, it’s outstanding. The ergonomics are purposeful. No question.

But the clip sppon is mounted across a section of handle that isn’t truly flat. And that matters for me.

That handle creates localized tension points. In pocket draws and insertion, that translates into friction. And friction, over time, translates into shredded fabric !!

For a knife that’s designed to live in harsh environments, the last thing you want is a clip that behaves like a textile rasp.

For the record, this is not a Salt-series indictment.

Neither the Spyderco Manix 2 Salt nor the Spyderco Paramilitary 2 Salt exhibit this issue.

A low tension deep carry clip helps a lot in my case but your mileage may vary in terms of keeping your pockets pristine…

Anyway performance remains uncompromised.

Having a true all-terrain Military is no longer a niche concept. It’s a must.

The original Spyderco Military was conceived as a purpose-driven field knife — large, lean, unapologetically performance-focused. It wasn’t built for desk duty. It wasn’t built for Instagram. It was built to work.

Today, “field use” doesn’t just mean dry land and predictable climates. It means:

- Coastal humidity

- Saltwater exposure

- Sweat-soaked summer carry

- Snow, mud, rain

- Long-term storage in less-than-ideal conditions

- Kitchen !!

Corrosion resistance is no longer a specialty feature. It’s a baseline requirement for a all terrain purposed tool.

Low maintenance is a true luxury.

All inner parts are coated but the stop pin and the washers.

Notice that beautiful G10 layers a tour-de-force.

The nested liners being all coated there is no excuse to use that knife in wet environment.

That’s why the Spyderco Military 2 Salt matters.

It closes the loop of reliability through 3 decades.

The Military platform has always chased the frontier of steel performance — from ATS-34 to particle metallurgy, from high-vanadium experiments to modern wear monsters. But performance isn’t just edge retention charts and carbide percentages. Real performance includes survivability.

An all-terrain Military folder means:

- A blade steel that shrugs off salt and sweat

- Hardware that resists oxidation

- A platform you don’t have to baby

It becomes a knife you can carry on a boat, on a mountain, in tropical humidity, or clipped inside gym shorts without thinking about it. The list goes on but you catch my drift. The Military is a big light hardchore folder ready to get dirty.

And that last part is key: without thinking about it.

Because the ultimate evolution of a military all terrain tool isn’t higher hardness.

It isn’t more vanadium.

It isn’t better CATRA numbers.

It’s freedom from worry !

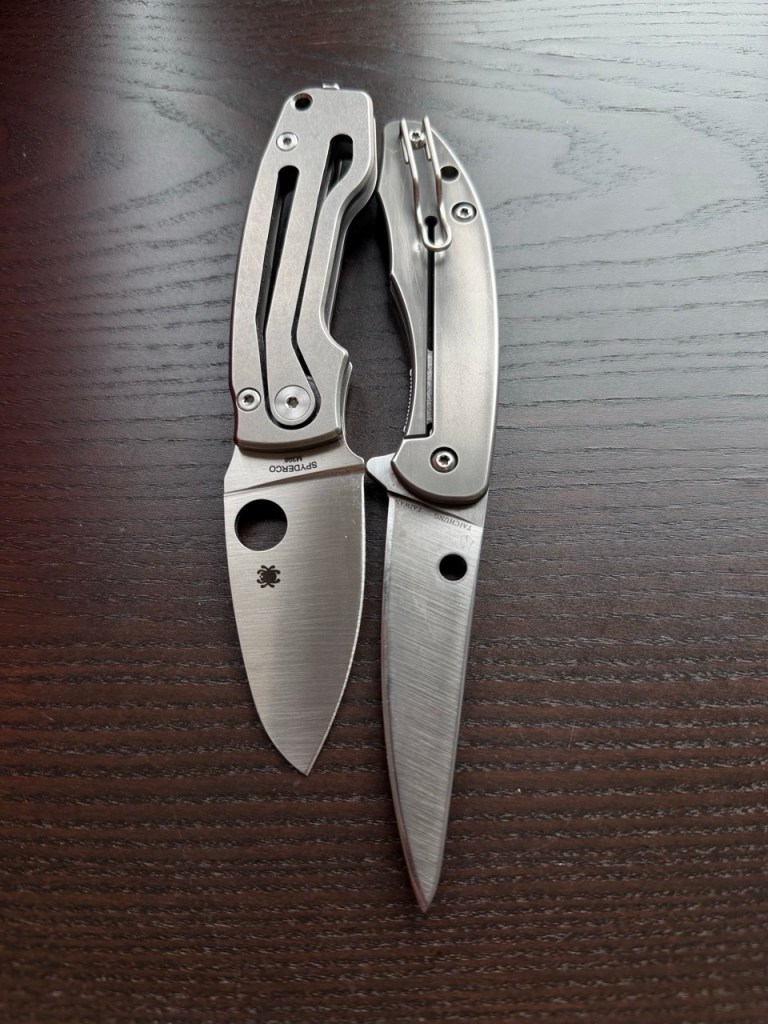

The Spyderco Military 2 Salt benefits enormously from the Compression Lock. The action is smooth, controlled, and confidence-inspiring. Opening is fluid. Closing is effortless and safe. Lockup is rock solid — zero play, zero drama.

It feels modern and mechanical in the best possible way.

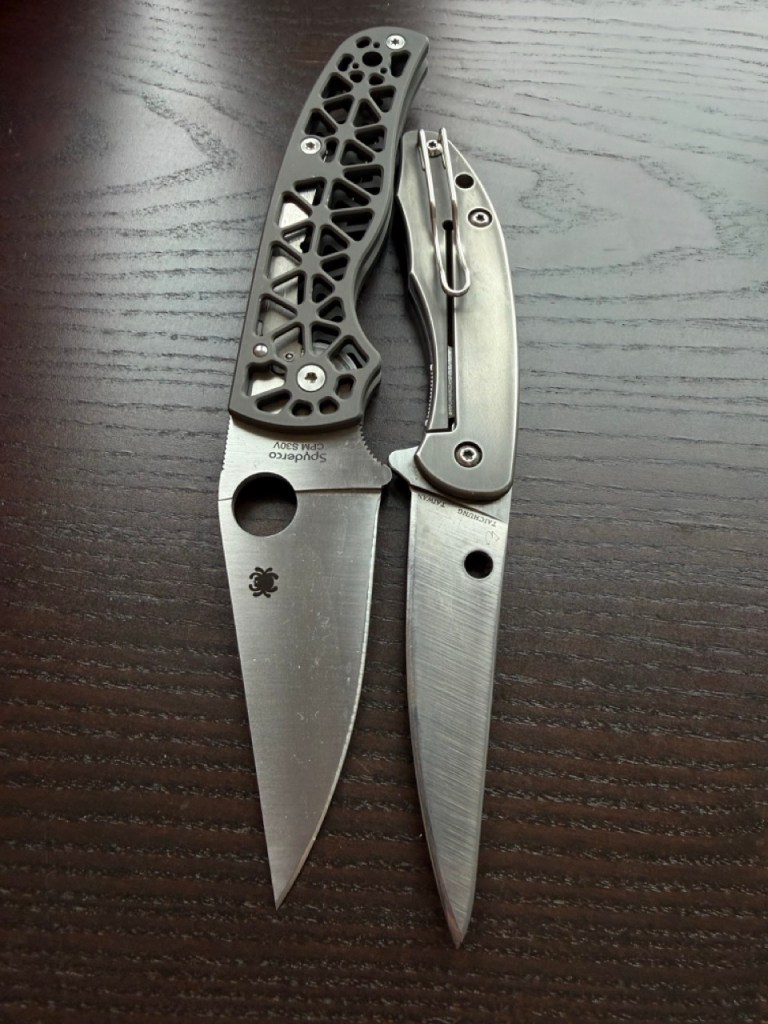

Compare that to the Spyderco Native Chief Salt Lightweight, and you’re in a different world. Back lock instead of Compression Lock. A more traditional cadence. A different relationship between hand and blade.

Both are outstanding knives. Choosing a favorite isn’t about quality — it’s about preference.

The Lightweight Native Chief is that good. 😉

The same goes for the Spyderco Sage 5 Salt.

Compact. Refined. Exceptionally balanced. In Salt configuration, it becomes one of the most complete corrosion-resistant EDCs available today.

At this level, it’s no longer about which one is better.

It’s about which one feels like yours.

The Military was once the knife that introduced mainstream users to particle metallurgy. Now, in Salt form, the Military 2 introduces the idea that a full-size, high-performance folder should be truly “environment-agnostic”.

And if we’re honest — for a knife with “Military” in its name — that capability feels less like an upgrade and more like destiny.

I had named my CPM M4 Millie “Ghost.”

My grey CPM CruWear Millie became “Gandalf.”

My current 15V Military 2 is “Gambit.”

So the salty one needed a name too.

And it had to start with a G.

It will be “Gurney”.

Gurney Halleck in frank Herbert’s Dune isn’t the flashy hero. He’s not mysticism and prophecy. He’s discipline. Loyalty. Hardened competence. A loyal warrior-poet who survives harsh worlds through skill and resilience.

That’s exactly what the Spyderco Military 2 Salt represents.

Not ornamental.

Not fragile.

Not trendy.

It’s a knife built for hostile environments. A blade you trust when conditions turn abrasive. There’s something very Arrakis about a corrosion-proof Military: survival through preparation.

“Behold, as a wild ass in the desert, go I forth to my work.”