Here it is the Benchmade Adamas second generation with its CPM Cruwear heavy duty blade.

It has been almost 20 years since I have reviewed one of Benchmade hardchore (made for the Military) folder. The last one was the AFCK Axis in D2 and I even think it was not upload even if it was my EDC for two years. I loved the AFCKs because, well, Sal Glesser was involved in its design with Chris Caracci and Les de Asis and Bob Terzuola and I simply appreciate Sal Glesser’s way to invent and design “matter separators”.

But here it is “Tabula Rasa” as far as I am concern ! Go figure: no hole in the blade, but holes in the handle, a gifted designer which I’m going to discover named Shane Sibert who has also designed the Bushcrafter for Benchmade… and Clive Owen’s knife in Sin City.

His signature seems to be fuller on his blade.

“I started making knives in 1994 with the idea of creating blade ware that is simple, practical and efficient. I have been a full-time knifemaker since 2004. Keeping with the theme of practicality, I avoid large metal guards, bolsters and heavy pommels to keep the knives balanced and agile in the hand. Materials have been carefully selected to ensure optimal edge retention and low maintenance. Although the knives incorporate slim handle slabs to decrease unwanted bulk and weight, the handles contour the hand for a synergistic fit. I strive to hold myself to high quality and design standards and produce a knife that will invoke pride of ownership and at the same time perform the task that it was designed for with exceptional ease.”

(quoted from Arizona Customs Knives)

You can notice slabs and hole on the handle.

Actually for such a big knife the Adamas is not that big.

The first version was release in 2011 (you can see it here on Arizona Customs Knives) and was made of D2 the new version came ten years later and with its blade upgrade to CPM Cruwear.

This steel is known to be tough ! Less than CPM3V but with a better edge retention. The Cpm Cruwear Shaman was a big hit !

Here Benchmade has heat treated the CPM Cruwear to 63-65 HRC !

This is something I need to test as it is much harder than Spyderco HRC (61-62HRC) on their CPM Cruwear blades. (Sal tested his own blade at 61.1 HRC).

Cruwear Manix 2 – (63.2 – 63.7) HRC

Cruwear Military – 62.9 HRC

Cruwear Mule (re-release) – (62.1 -62.8) HRC

Cruwear Paramilitary 2 – (62 – 62.8) HRC

Cruwear Para 3 – 61.7 HRC

Cruwear Military – 61.1 HRC

At first touch, the Adamas oozes quality and delicate attention to details. The Olive Drab G10 slabs are wonderfully tappered on both ends and the jimping is done perfectly in my book, not as aggressive as G10 Manix for example. It is palm friendly even when closed. Well done. The holes in the handle help my thumb to index the tool.. There is no hot spots. The handle is totally open and easy to clean and check for debris. It is created as a workhorse which can get dirty but still reliable.

Of course this is an expensive knife with a MRSP at $280.00 but you can see where your money has gone. It is manufactured with love.

The blade is perfectly centered on mine and there is zero blade play in any direction.

I love the Axis Lock concept since its very first Henry&Williams BM710 release.

I have never had any issue with its Omega Spring. It is easy to use with one finger when the SPyderco Cage Ball Bearing needs two finger to work. The Axis Lock makes any knife as fast as automatics. I have never had any play on mine and I have been using them since their very very first release.

I won’t do batonning with the lock engaged like some youtubers seems to do until lock failure. For record, you can do batoning with an opinel…

But engaged lock (any lock) does not like to schoked and a beating can damage an disengaged any lock even a butterfly. Knowing how to use tools in the right situation should be mandatory before doing really stupid things on video and if anyone want to use a folder for batonning some wood (stupid millennial fashion as far as I am concern) just do it with no lock engaged or learn how to bring a better tool…

But once deployed, with just a gentle flick of the wrist — axis lock with heavy blade are just extraordinary easy to deplay— the blade is shown in all its power. I understand why some youtubers would like to shove it in concrete or in bricks…. I’m not certain they will be able to peel an apple in public with it but for that kind of task a Mini Adamas has been released with the same blade thickness…. Oooh well I’m not certain the thick Mini Adamas is made for fruits either. F<or that there is another tool too: the Kapara…

The Adamas offering a 0.14″ | 3.556mm thick blade, it is designed hardcore for hard chores for folders. How will it behave, that will be in our next article but that blade surely offers a lot of lateral strength.

For now it is just a very first glance.

All specs of the Adamas can be found on Benchmade here.

You can also notice on that picture its deep carry clip which can be a nice touch for such a big heavy folder. More on that later.

The action is smooth at the pivot but needs a little breaking at the lock release; nothing some nano oil can not fix.

This is a very beautiful folder which is very well balanced, its sweet point being just under the index finger when hold in hammer grip.

It is alive in my hands.

The axis lock makes it ambidextrous and you can notice on that picture the 3 points for adapting that clip or another three screw clip (not deep carry) if needed on both sides of the handle.

The blade handle ratio is almost to 1 with the Adamas compared to the Military C36 which is known for its long handle.

Of course the Adamas came very sharp out of the box, but not as sharp as I want. The blade is protected with cerakote coating Flat Earth colored which got excellent reputation in terms of tough protecting the CPM Cruwear from rusting. Cruwear can get a patina but it is not easy.

Here Benchmade and Shane Sibert have chosen to propose a stealthy look for the soldiers which need no blade reflection under the sun too.

It is also sold with a very nice sheath offering many carry options for soldiers and hunters alike.

The deep carry clip is perfect in term of retention and ease to retrieve the big and heavy knife.

Oh it is 183 grams (5,45 oz) which is really heavy. The liners are stainless steel not titanium. This is Heavy Metal !

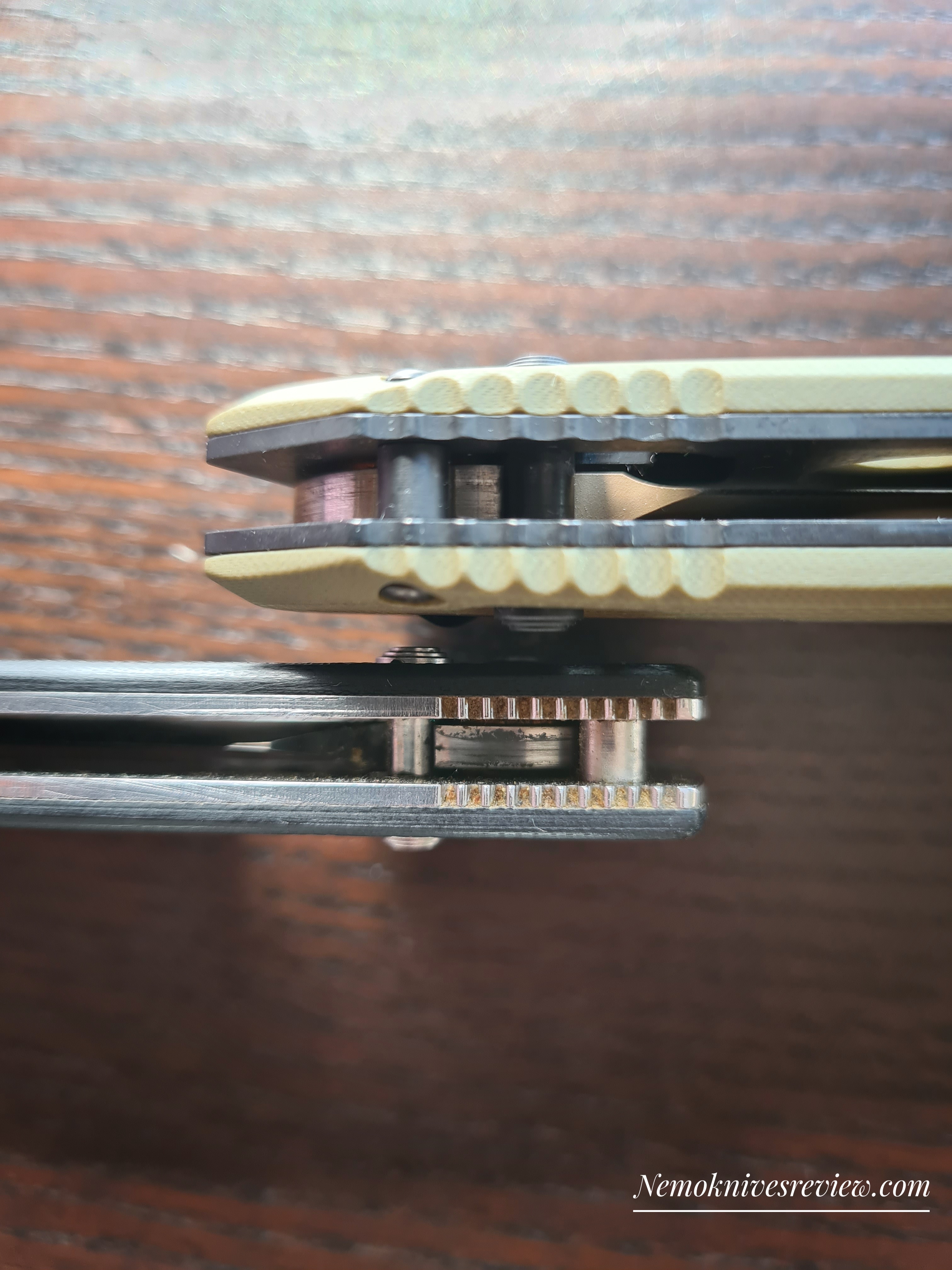

As you can notice the Adamas is much thicker than the C35 Military and much heavier too. Sal Glesser wanted his military to be as light as possible as a soldier got already many heavy things to carry.

Benchmade has taken another direction. The Adamas is beefierand thicker. Actually it can also been more confortable for long usage. We will see…

Another beefy released was the Shaman which almost has the same handle length. The Adamas provides a lot of edge.

Here is my good old AFCK Axis. It was used with a lot of love as you can notice. Zero issue with the lock BTW.

Now it is time to give some work to that Adamas designed to “deliver unrivaled performance throughout hard-use applications”. The next step will involve certainly some sharpening and reprofiling…

More to come soon…. But for now on, it is a knife which makes me grin when I open and close it. Kuddos to Benchmade and Shane Sibert for bringing this second gen of the mighty Adamas.

(Bud Nealy’s knives were sold as “fast response defense knives”. Here a Peshkab near a Spyderco Mantra 2 for scale purposes.)

(Bud Nealy’s knives were sold as “fast response defense knives”. Here a Peshkab near a Spyderco Mantra 2 for scale purposes.)

The Nimravus in M2, and pictured : the mini Nimravus BM45HS.

The Nimravus in M2, and pictured : the mini Nimravus BM45HS.