“You sharpen the human appetite to the point where it can split atoms with its desire…”

I feel like in the “Honest Trailers”: “Please review the Advocate…” OK here we go:

Oh yes, the Advocate is a looker and really catches the light. Knowing Gayle Bradley since his first hard chores folder, I really wanted to see his new design.

At the moment I write those lines, we are all under the official statement from Spyderco about the Advocate. To sum it up: “A careful review of the Advocate’s design revealed that the steel washers used in its pivot are measurably thinner than those used in our other flipper models and are therefore vulnerable to the effects of overtightening….We have suspended production of the current version and are working diligently to redesign the pivot to completely eliminate this concern. We have also decided to suspend shipment of our current inventory of Advocate knives until a satisfactory redesign is complete.” Michael Janich 10th of April 2017.

I don’t have any issues with my Advocate pivot, so I’m not concerned.

Unless major purpose, I don’t feel the urge to disassemble my knives and I always find that rinsing them under hot tap water and oiling them back once dry, is more than enough to keep them going. I do however have got a gripping pivot issue with my Southard but this was before discovering and using nano oil. Here on the advocate, it seems like even nano oil did not help. but again It do not have any issue on mine. I got other issues and they are from the design, not the manufacturing.

So I was able to snatch a model before the factory line stopped and I really wanted to try and love another great Gayle Bradley design. The Advocate is his first flipper and he’s using my favorite steel: CPM-M4 (drawing from Gayle Bradley’s extensive experience as a competitive cutting champion, CPM® M4 is a high-performance tool steel renowned for its extreme edge-holding ability).

“The Advocate’s handle consists of two 3-D-machined solid titanium scales that are radiused across their width and feature a unique “orange peel” finish that is both visually striking and provides an enhanced grip texture. The precision machining of these features ensures maximum comfort in the hand and contributes to the knife’s stunning, custom-quality appearance.”

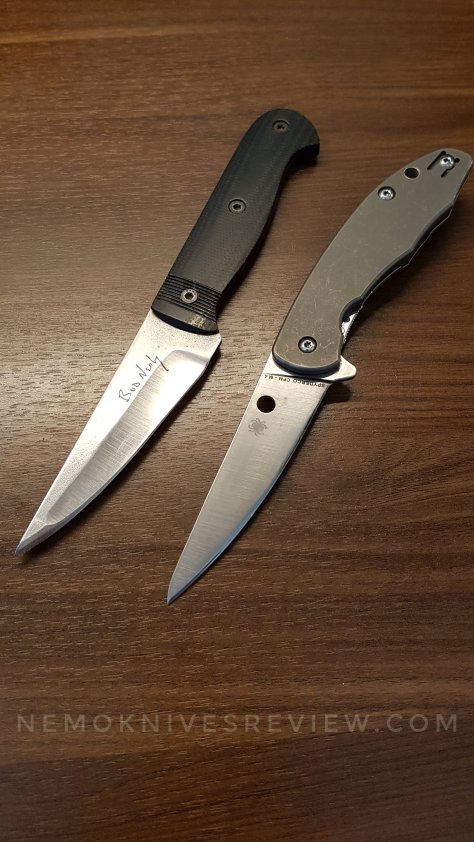

See how the knife looks great? This is a very thin design. It slips into your pocket very confortably but, in my own experience, its thin handle create a lot of hotspots. I would have preferred a thicker handle even if the finish and lines are wonderful, it is really more a looker than a user so far.

OK mine fires perfectly and once unlocked, the blade falls free. So the action is OK but there is a strong break to it: the ball detent on the lock making the action less smooth than on my other flipper: ZT0562 or Falcon. It’s even noisy, you hear it. What is the point of having ball bearings when you put a brake on it ? Spyderco knows what smooth means ie Ed Schempp’s Bowie the Paramillie. Why not the Advocate ?

Also you can notice how the Zero Tolerance’s (ZT) handle is thicker and hence much better ergonomic-wise. I would not mind that for a

Chaparral or for a shorter folder but the Advocate is a medium folder with a 9 centimeters blade and weighs 111 grammes; so it’s not a small folder! Even on the last picture you can see that it’s thinner than the Sliverax….

Error

This video doesn’t exist

Also flippers have got a fun factor shared with spinners and balisongs. We love to play with them and because of that, we have tendancies to “test” them more in their opening and closing.

Again, the Advocate’s thin profile doesn’t make it easy to close. The tension on the lock bar is very important and the edge to unlock it is sharp. So it’s not easy on your thumb, almost painful sometimes compared to my ZT and its fat lock… Even the flipper’s tab feels too thin for such a strong detent. It’s biting into the index finger’s pulp….

You can see the sharp edge of the lock bar; actually it comes from the steel insert.

You can notice the marks on my thumb.

Look at the way the lock bar is chamfered on the ZT. Rick Hinderer is not at his first flipper design obviously…

After playing for some time, there is no real fun. The detent is so strong it makes thumb-opening impossible on mine; only reverse grip works for me.

Error

This video doesn’t exist

So the strong lock acts like a break; you understand why Compression Lock flippers like the Sliverax are a path to explore. That said, after playing with both knives, I also feel the Sliverax could have benefited from a stronger detent.

So far the Advocate is not my favorite Gayle Bradley design.

My opinion is not based on any pivot issues as mine doesn’t have it but in my book,

it’s too thin, too slippery, not easy to close nor is it easy to open with the thumb hole. It’s not smooth… It’s the total opposite to its famous GB1.

Perhaps it will grow on me but even the clip is not a deep carry option… Oh well.

I need to play with my Ed Schempp bowie for good measure… as it’s the perfect opposite in the way Taichung can deliver a great folder with great ergos.

So in summary, if you want a really fun and light Spyderco to play with, try the Sliverax.

edited by pjaffre: jan 5, 2018.

The Nimravus in M2, and pictured : the mini Nimravus BM45HS.

The Nimravus in M2, and pictured : the mini Nimravus BM45HS.

Bud Nealy Pesh Kabz or Travel Knife in M2 the coating has been removed and the Mantra 2.

Bud Nealy Pesh Kabz or Travel Knife in M2 the coating has been removed and the Mantra 2.