Article written by Nemo Sandman – Edited the 12th of December 2022.

All rights (pictures and text) reserved.

Have you ever asked yourself why they are so many Spyderco Sprint Run released (out of the blue most of the time) with gorgeous carbon fibers handle and impressive CPM S90V blades ?

Because Sal Glesser loves both materials.

CF is for him a reminiscence of love of motorsports and S90V is a stainless steel which has proven to be in another league in terms of high performance and reliability.

So, long story shorts:

Full Flat Grind +Carbon Fibers+ S90V = Sal Glesser’s favorite combo !

And to quote my friend Spydercollector:

“When the Bushcraft fixed blade was first announced, Sal also planned to do a so-called NASA version; a version of the Bushcraft knife with all high-tech materials. I believe NASA is a protected name, but Endeavour still evokes the high-tech approach most people associate with the famous space agency. The Endeavour features a full flat grind S90V blade and full sculpted carbon fiber handles. It was a beautiful knife with a grip that had me looking around for stuff to cut.”

https://spydercollector.wordpress.com/tag/chris-claycomb-endeavour-prototype/

Here is the Proficient: it is designed by wilderness expert Chris Claycomb of Bushcraft UK, the Proficient functions perfectly with traditional bushcraft skills and cutting methods. Carefully contoured and polished to eliminate hot spots and ensure maximum comfort during prolonged use.

https://www.spyderco.com/catalog/details/FB36CF/Proficient-trade-/943

Bushcraft knives have specific parameters such as having blades between 4-6 inches. Spyderco’s is typical of the genre with a 4-inch blade (no handguard) that’s fully-tanged.

Bushcrafters don’t seek the characteristics of stainless over the performance of high-carbon edge retention and this is why traditional Bushcraft knives are produced using tool steel. O-1’s high carbon content offers long-term cutting retention but sharpens easily when laying on a new edge. The knife carries on a belt or strap encased in a leather sheath. Blueprinted for wilderness chores, it slices, chops, whittles and processes game in traditional Bushcraft style.

To quote Spyderco:

“The Spyderco Proficient takes the concept of the traditional “do-all” bushcraft knife and elevates it to new levels of performance with state-of-the-art materials and manufacturing methods. Designed by wilderness expert Chris Claycomb of Bushcraft UK, the Proficient functions perfectly with traditional bushcraft skills and cutting methods while offering superior durability, edge retention, cutting performance, and corrosion resistance

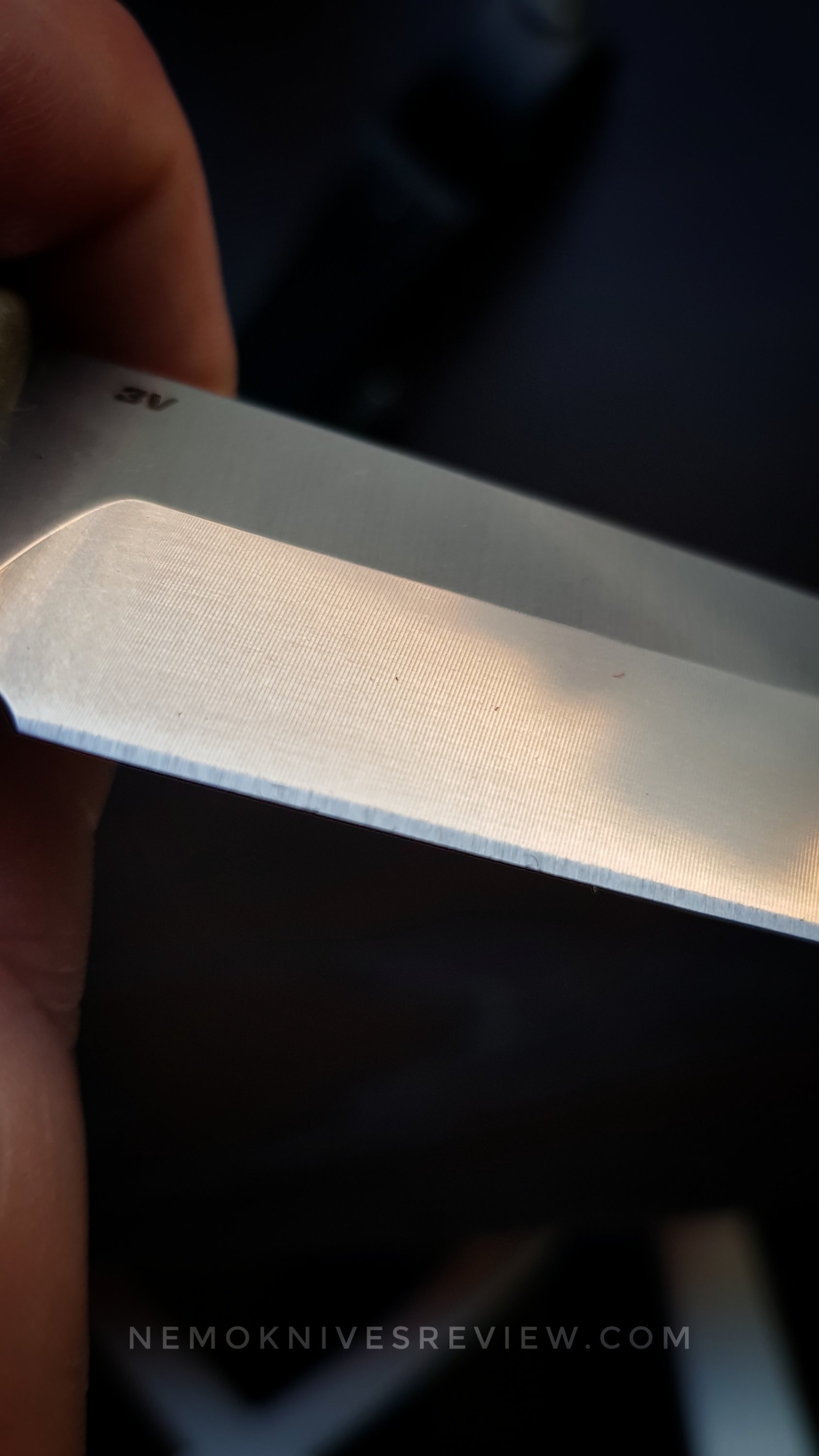

Instead of traditional carbon steel and an axe-like “Scandi” (Scandinavian) grind, the Proficient’s blade is crafted from vanadium-rich CPM®S90V particle-metallurgy stainless steel and boasts a full-flat grind for low-friction cutting performance.“

This concept of stainless steel with black polished handle is, ten years later, now endorsed by the excellent Casström No. 10 Swedish Forest Knife Black Micarta, 14C28N Flat Grind for example.

I had tried and discovered CPMS90V when it was called CPM420V thanks to Darrel Ralph (RIP) and his beautiful Apogee folder. Its blade was so wear resistant, without diamonds, only a back stand could turn it from dull to sharp. It was a bear to sharp.

It still is but now we got as End Line User access to industrial diamonds.

I have written a lot about S90V. This alloy has proven it can be tough enough as a stainless steel to be used in any all terrain tools; especially since it is available on Manly folders which got the reputation of using a very fine thin geometry on their blades.

Modern Bushcrafters (like the Benchmade Puukko) are focused on toughness with the use of the very tough CPM 3V.

What brings CPMS90V ?

1- It is stainless ! Even if you (and I) love the patina on a great carbon steel blade, to hold a reliable stainless steel blade is very easing the mind when working near water, rain, sea.

2- It is really hard to get dull even when used on tricky material like brown cardboard (full of silice).

Also the full flat grind is a must in a matter separator specialized in wood works. As much as I love Scandi Grind found on Woodlore clones (first designed by Ray Mears).

I have found that especially in the wonderful Spyderco Sprig full flat ground knives can be really efficient on hard wood.

(BTW when the writing appears in green: it is a link !! and I have tested them here.)

The Sprig was really an impressive tool in term of pure geometry. Designed as a hunting fishing knife, it was a wood eater, a real beaver of a knife, cutting deep and with ease.

Guess what? It the same profile on the Proficient especially after some convexing which should be arriving sooner than later and will be in a second article.

So far that contour handle is a charm to use and I will be using it for the second article. The old O1 Bushcrafter got enough heft for light chopping, the Proficient is made for powerful push cuts. This is going to be another experience.

The Proficient is not a big knife, actually once in its sheath, it can disappear in the front pocket of my Denim. No need to have dangling at my belt.

So what do we got ? Imagine the plateforme of the Bushcrafter (link) a solid companion, a reliable 4×4 and you just turn it into some Urus from Lamborghini: stellar alloy and lighter tougher handle.

What not to love ?

The Proficient is Sal Glesser’s gambit, taking a risk because the Bushcraft community loves carbon steel and wooden/natural handle.

Also that jewel got a price. And people in bushcraft are not wall street sharks. They use Opinel, Mora and at great max some 100 euros fixed blades. (Unless they want to afford an original Woodlore….)

So the stealth wealth of that Nasa Bushcrafter was not for everyone.

Like a Lambo actually. But real performance got a price.

Article written by Nemo Sandman – Edited the 12th of December 2022.

All rights (pictures and text) reserved.

That handle is made in some kinf of thermorun… but it is rubberized Santoprene is a soft, non-hygroscopic elastomer which exhibits excellent surface appearance, a durable soft-touch feel, excellent colorability and excellent “processability”… made by Exxon.

That handle is made in some kinf of thermorun… but it is rubberized Santoprene is a soft, non-hygroscopic elastomer which exhibits excellent surface appearance, a durable soft-touch feel, excellent colorability and excellent “processability”… made by Exxon.

The knife snuggles perfectly inside the pouch you can pass in a belt.

The knife snuggles perfectly inside the pouch you can pass in a belt.

I had ordered a titanium deep carry clip for my

I had ordered a titanium deep carry clip for my  So here it goes !

So here it goes !  I’m always amazed at how thick the blade is and how solid this little folder is after one year without real maintenance. I have found the scandi S30V quite easy to maintain razor sharp and to my surprise it is easy to keep that way without any convexing and losing the “zero ground” scandi edge. But the best thing about the Wolfspyder is how hard

I’m always amazed at how thick the blade is and how solid this little folder is after one year without real maintenance. I have found the scandi S30V quite easy to maintain razor sharp and to my surprise it is easy to keep that way without any convexing and losing the “zero ground” scandi edge. But the best thing about the Wolfspyder is how hard Easy to carry and easy to reach in the pocket. This one will be in my pocket for a trip in Norway very soon ! The Scandi ground little big knife in Scandinavian territory !

Easy to carry and easy to reach in the pocket. This one will be in my pocket for a trip in Norway very soon ! The Scandi ground little big knife in Scandinavian territory !