Being the son of a legend is not easy and it’s not because you are shorter that you need to develop some complex. Designed by Sal and Eric Glasser, the Paramillie 2 is simply gorgeous.

Since its first incarnation, it did not walk in dad’s footsteps: the smaller version was using another lock than the good old linerlock (I love liner locks !) but the Compression Lock developped for Martial BladeCraft. This was the kind of lock you could find on the Yojimbo and the Lil’ Temperance and on the Gunting (but mounted on the opposite liner). The Compression Lock is strong reliable, easy to clean and was a great addition. Also the knife is so well made, the blade can be flicked in close position just by releasing the lock. This is a gravity knife for closing purposes.

The second version of the Paramillie got a longer blade, some ergonic improvements and a bigger lanyard hole. This is a very well balanced and homogenic package who offers the same “cockpit” of the C36 Millitary in a more civilian way. The cuts are equally strong as with the C36: the Paramillie keeps the same geometry (with a lil’ even more belly) than its dad.(*)

Anyway, The first thing I have made when I have received my Paramillie 2 was to turn it thick G10 handle into a more “trouser friendly” version: sanding the grippy G10! (Also I get so much used to Carbon Fiber that I wanted to have the same feel…)

I prefer my handles softer than the factory’s one. G10 can be used to file the linen of your pocket and I don’t want holes.

After sanding it (beware the micro dust of G10 which is highly toxic!) I have polished it. I’m happy with the result. Grippy handle can be handy but once sanded my handles keep a positive grip without the side effects of filing fiberglass.

I also found the shiny clip a little to shiny for my taste. So I have switched it with my Gayle Bradley bronze clip. The result is more stealth for the city.

The GB clip screws are a little longer (and the diameter is perharps a little thinner) but it worked perfectly. Also the Gayle Bradley’s clip is known to keep its appearance for a long time. (mine is one year old and looks like new!)

There is another plus with second version: you can positionned the clip in four ways. So As I want to use my Paramillie in the wood and hard material, I have decided to reposition the clip Tip Up / Left Handed way.

(I’m right handed)

Why ? Because there is no more metal clip against my palm: no more sore or hotspot.

And thanks to it very large blade hole I can even open it in reverse grip easily.

The balance on the Paramillie 2 is perfect. The knife is very “alive” in the hands. No bladeplay what so ever, great ergos…

I have already test it on my Bottle Butt test and it has passed it with flying colors !

On this picture you can notice how the G10 looks once sanded. And also both signatures of Eric and his father Sal ! This is the very 1rst Spyderco knife which got both !

I will update this post later, but for now, I think I have found the perfect folding match for my G10 Bushcrafter.

Also I have gently convexed the edge like I have done on my Sage II.

**** edit****

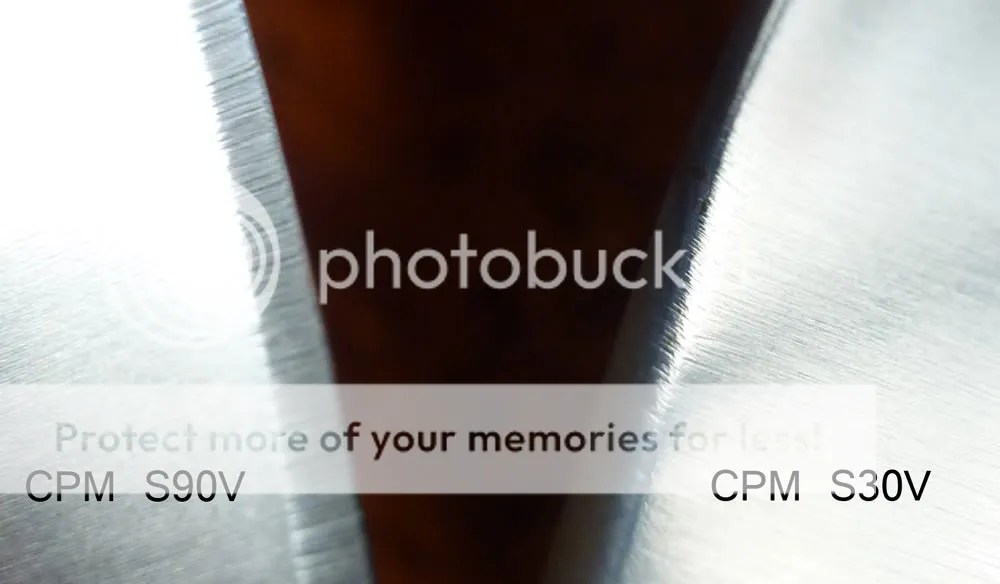

(*) eventually a picture worse a thousand words:

Update of the 10th of March 2011.

Here are some pictures of the S90V/CF sprint run of the Paramillie 2. This is a dream come true folder: since the release of the C36 Military: a compact package and upgrade materials. I recognized to have been traumatized by Phil Wilson’s articles about S90V (CPM420V) in 1998…

I have gently sanded the Carbon Fiber handle just to remove the biting. I don’t want to get a polished handle like on the G10 version.

On this last picture you can compare the edge of my polished CPMS30V Paramillie 2 blade and the CPMS90V (HRC60) which has been stropped for four days without any polishing improvement but the edge is incredibly sharp.

The blade is cutting meat like hot butter…

This a folder which is meant to be used and get dirty !

I have sanded the handle to smooth it and also the “hump” which can file your trouser at each extraction of the knife frome the pocket:

Now I can carry it “Tip Down” and open it with the SPyderdrop which is IMHO the most elegant way to open a folder.