Disclaimer: The Spyderco Triangle Sharpmaker Diamond Rods Set of 2 – 204D was provided by Golden, along with the Caly 3.5. This article is the perfect opportunity to put them to the test.

The Sharpmaker is my own.

In the parcel from Golden were also two sets of rods: the 204CBN Cubic Boron Nitride rods and the 204D Diamond rods. Since my Caly 3.5 needed some convexing, it was time to see what these rods could do.

But you know, I’m a freehand sharpening guy. I don’t like being locked into fixed angles. I prefer to adjust pressure and movement based on what I feel directly from the blade against the rod. That’s why I’ve never been too fond of “systems” that take control away from your hands.

For me, sharpening should stay super simple, and—most importantly—adaptable. If I’m in the wild, far from the workbench, I still want to be able to bring an edge back with nothing more than a rod, a stone, or even something improvised.

That’s where the Spyderco Sharpmaker is different. It’s a system, yes, but it doesn’t dictate the process. It allows me to sharpen by feel, with freedom, and still gives me the precision I want.

Exactly — and that’s one of those clever little details only Spyderco would think of.

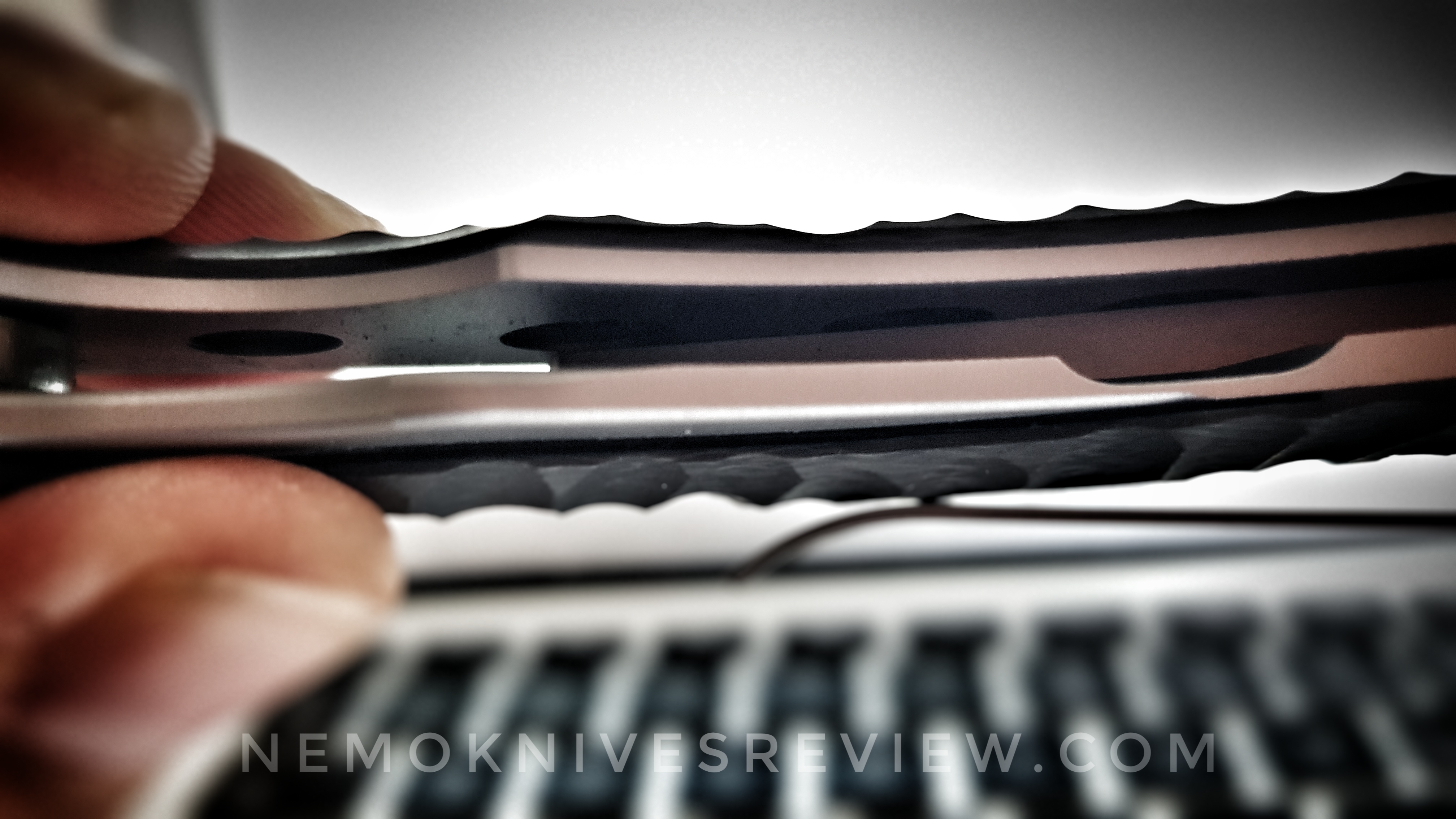

On the back of the Sharpmaker base, you’ve got two horizontal grooves that let you lay the rods flat. In that configuration, the tool basically transforms into a bench stone. With the diamond rods mounted this way, it works like a compact, portable diamond sharpening stone, letting you go full freehand.

So you get both options: the guided 30°/40° setup if you want consistency, and the freehand mode if you prefer to feel the steel, control pressure, and chase your own convex. That versatility is what makes the Sharpmaker more than “just a system.”

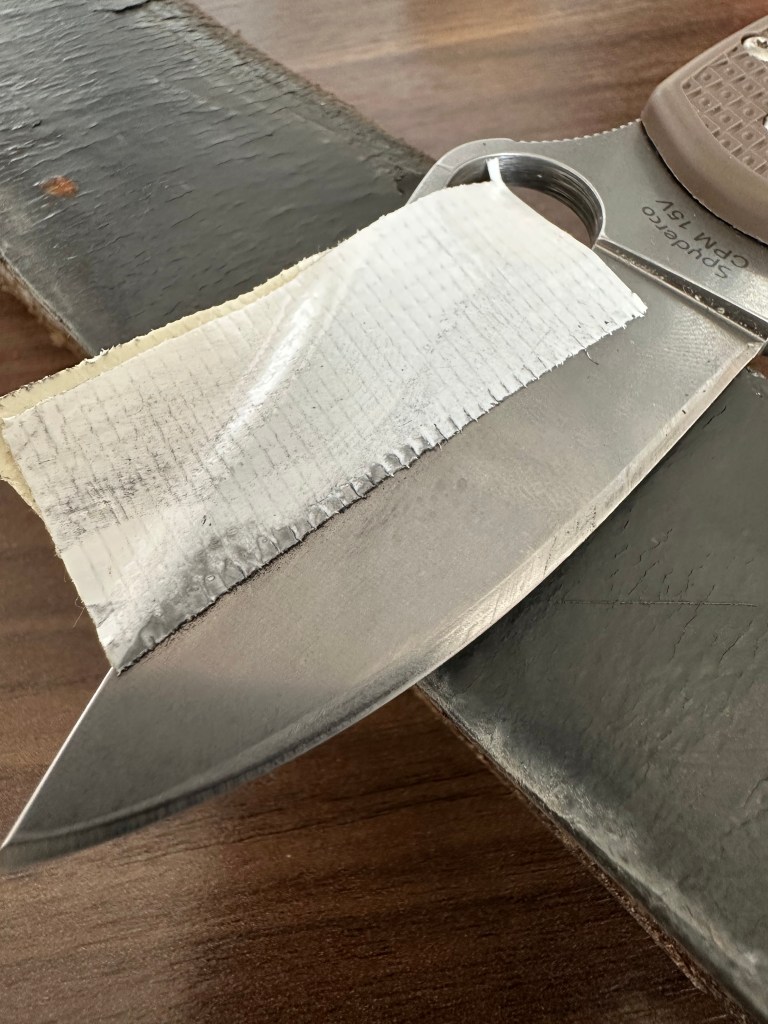

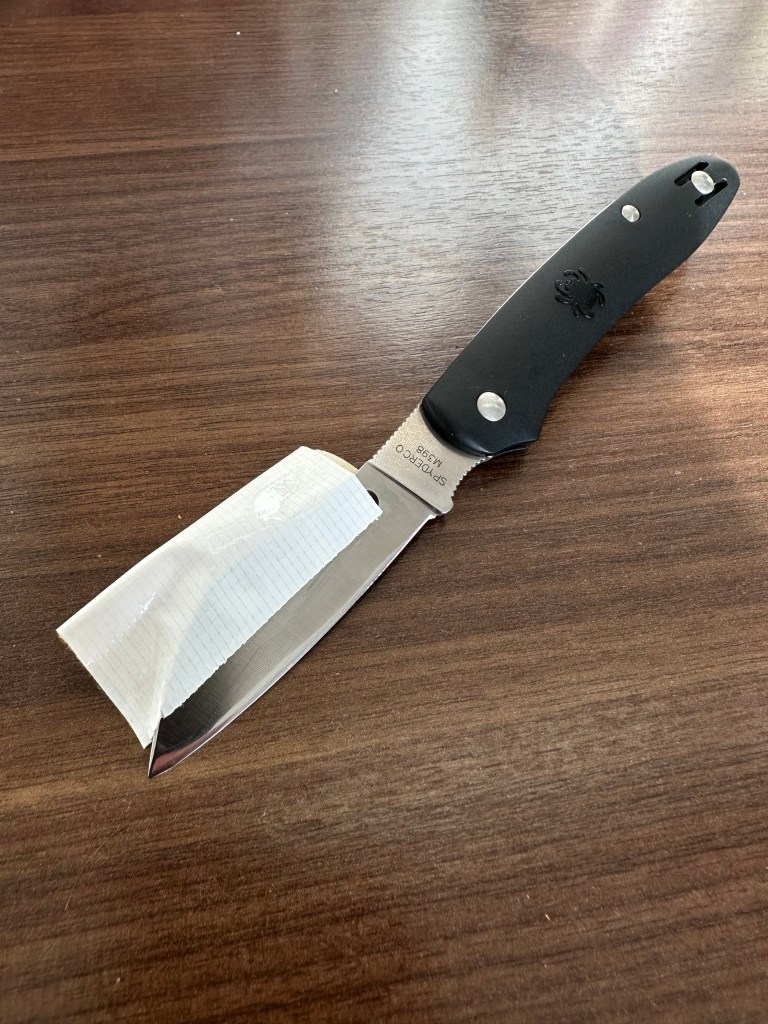

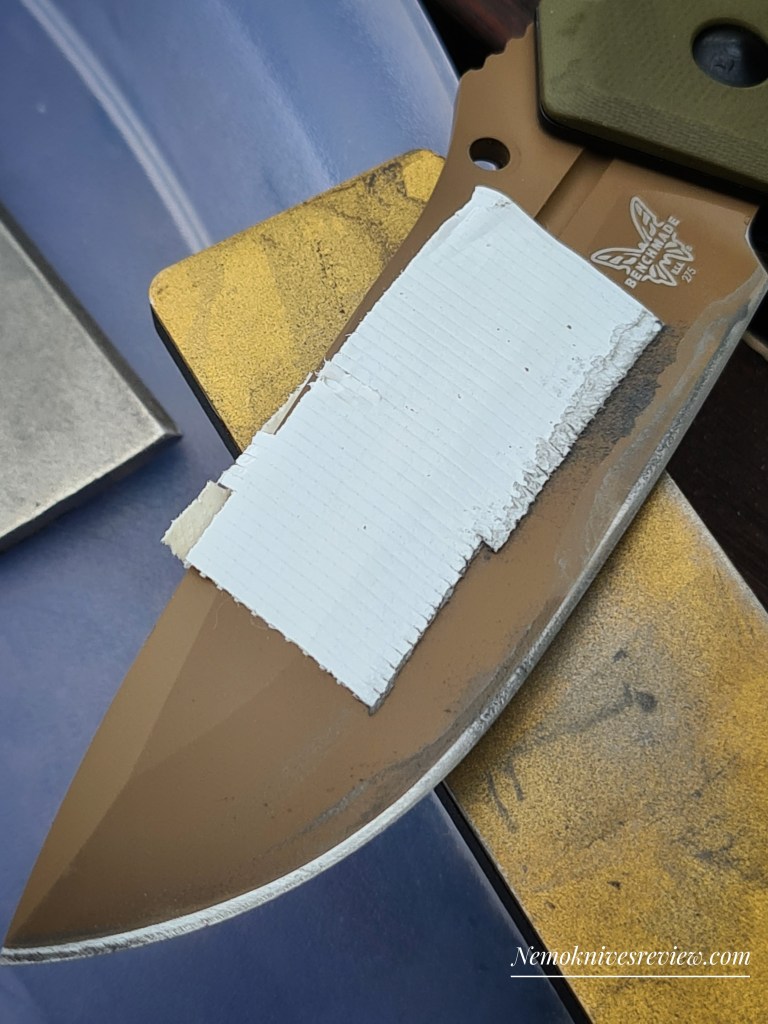

The gaffer tape trick is smart: it saves you from accidental slips while keeping the grind line safe. And yes, the 204D diamonds are hungry — they bite into ZDP-189 without hesitation, which also means they’ll scratch anything that touches them. But like you said, a working knife will earn its scars.

Polishing can always bring back some scratchless shine, but what really matters is how the geometry evolves: a little convexing, a thinner edge, and suddenly the Caly 3.5 stops being just elegant — it becomes a laser.

That’s exactly where your knife starts to become yours.

The convexing not only boosts cutting performance but also gives the edge that organic flow — you can see it in the way the bevel catches the light. It’s no longer a factory grind; it’s a living edge shaped by your own hand. It makes the knife more precious.

And by rounding the spine and softening the jimping, you’re turning what could feel harsh into something smoother, almost like a river stone. It transforms the Caly from safe queen into a companion you actually want to use every day, without hotspots or distractions.

Most people underestimate how quickly diamond or CBN rods load up, and how much that affects sharpening efficiency.

Clay stone (terre de Sommières, or even a simple pottery stone) is excellent because it’s mildly abrasive: it lifts out the embedded metal without scratching or damaging the surface of the rods, and it works faster than detergents or erasers.

It’s also in the spirit of my philosophy: keep it simple, practical, field-ready. No fancy cleaners, just a tried-and-true trick that works every time.

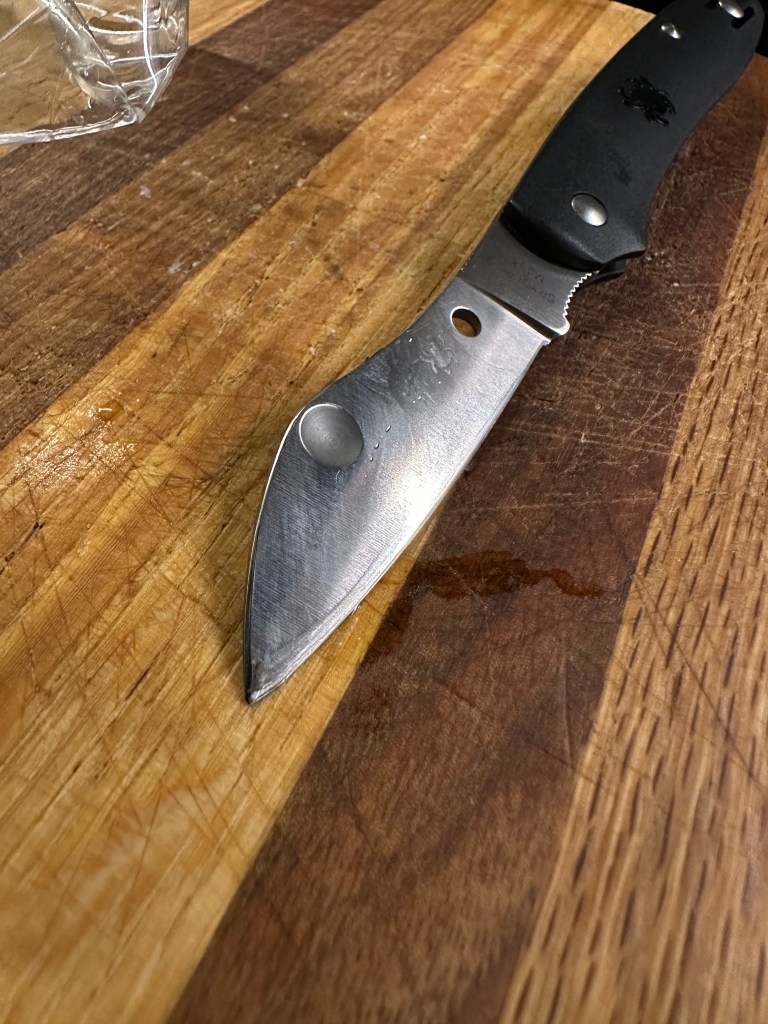

Dry chestnut is fibrous and can grab onto a thicker bevel, so the fact that your convexed ZDP-189 now glides “like a razor through butter” is a strong demonstration that the edge mod really paid off.

Convexing changes everything. Once the edge’s shoulders are rounded, the edge stops fighting the wood. No more wedging, just a clean, controlled push cut — like sliding through butter, even in stubborn chestnut.

That’s where ZDP-189 really shines. Most steels would give up at this geometry, folding or rolling. But at 65 HRC, ZDP holds steady. You get the sharpness of a razor without the fragility.

And the Caly 3.5? On paper, it’s a gentleman’s knife. In hand, convexed and sharp, it’s a wolf in disguise. A refined tool that thrives on real work, not just resting pretty in a pocket.

Wood tells one part of the story, but plastic will reveal another — especially the stubborn bottom of a bottle. That’s where I’ll see if this convexed ZDP-189 edge can truly glide without wedging. I’ll update this post as soon as I get the chance to put it through that test.