Disclaimer: This knife has been provided through Spyderco’s Ambassador Program, upon my own request. Thank you to the Spyderpeople for letting me review it.

When a Workhorse Learns to Swim.

The Spyderco Manix & Manix 2 — The Evolution of a Working Icon

In the early 2000s, Spyderco found itself at an interesting crossroads. The brand had already earned a formidable reputation among law enforcement, military users, and serious enthusiasts for redefining what a modern folding knife could be: ergonomic, purpose-driven, and unapologetically functional. Yet many of its most popular designs leaned toward lightness and slicing efficiency rather than outright mechanical strength. The Manix was born from a different ambition—one that prioritized structural robustness without abandoning cutting performance. It was a back-lock with the same strength as the Chinook’s.

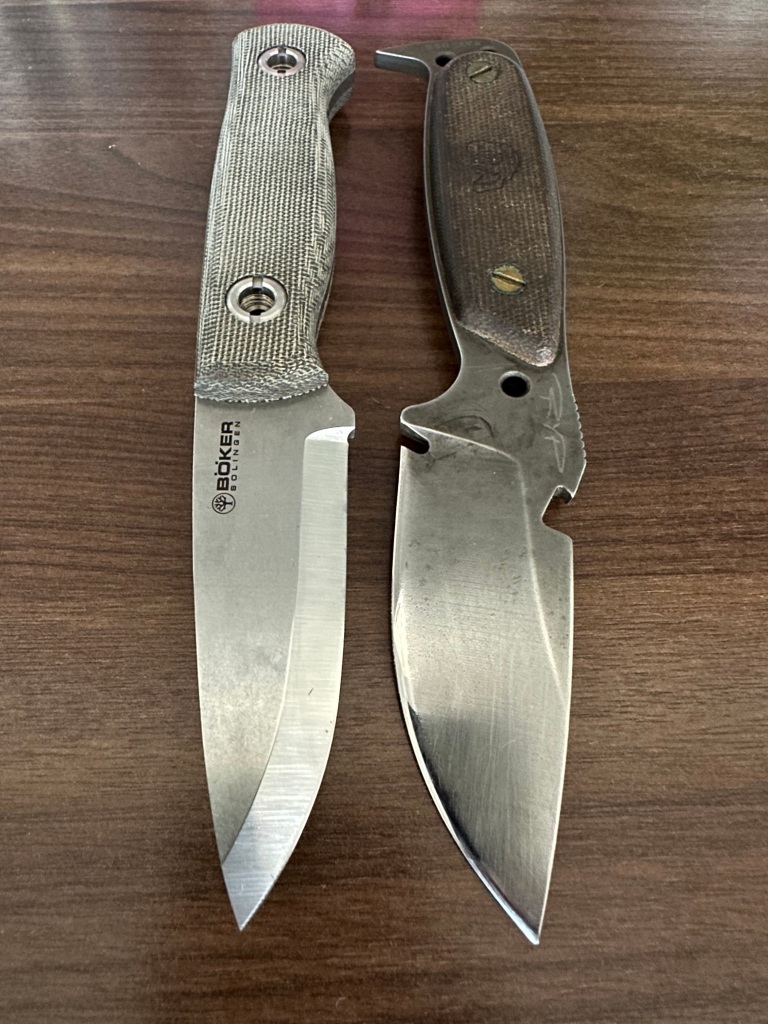

That original Spyderco Manix debuted in 2004 as a bold statement. Designed by Sal Glesser, it was conceived as a folding knife that could offer near–fixed-blade confidence.

The first Manix models were built like backlock tanks. They featured full stainless steel liners, thick G-10 scales, steel spacer and broad, leaf-shaped blades typically made from CPM S30V, which was then at the forefront of powder metallurgy steels. The knife felt substantial in hand, deliberately so and part of the Martial Blade Craft line. Its ergonomics emphasized control and safety: a pronounced finger choil, generous jimping, and a handle shape that locked the hand in place. In an era where many folding knives still mimicked traditional silhouettes, the Manix looked aggressively modern—and some might say unapologetically industrial.

Despite its strengths, the original Manix was not without criticism. Its weight and bulk limited its appeal for everyday carry. Spyderco listened. Rather than abandoning the concept, the company chose to refine it.

That refinement arrived in 2010 with the release of the Manix 2 designed by Eric Glesser. This was not a cosmetic update, but a structural evolution. The Manix 2 retained the fundamental identity of its predecessor while reengineering nearly every aspect for improved ergonomics, weight reduction, and usability. The handle profile was subtly reshaped for better comfort, the liners were skeletonized, and the overall balance was improved. The blade geometry was refined for smoother slicing without sacrificing tip strength.

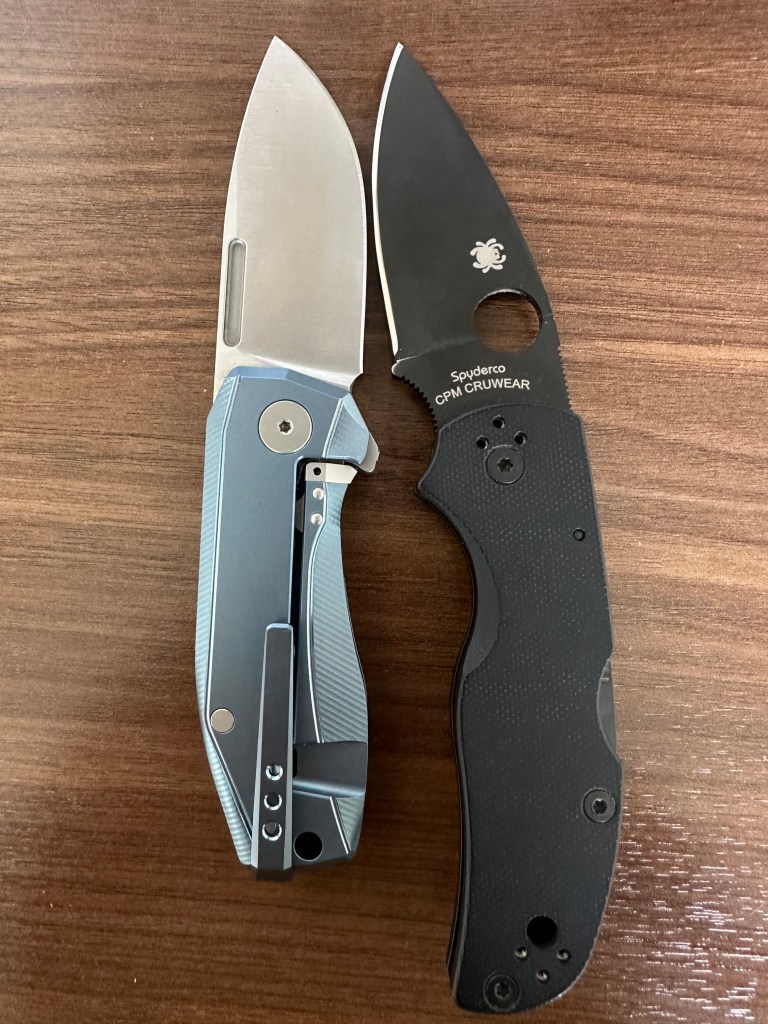

Crucially, the Ball Bearing Lock was first experimented on Eric’s Dodo and was redesigned with a removable cage, simplifying maintenance and paving the way for future customization. (FYI there was a Manix 2 with lockback.) The Manix 2 also benefited from Spyderco’s unique expanding steel portfolio, appearing over the years in everything from S30V and S110V to Maxamet, CPM CruWear, and later, CPM MagnaCut in the new Salt variants. Few knives have served as such a comprehensive showcase for the evolution of modern blade steels.

Over time, the Manix 2 became a canvas for experimentation. Sprint runs, exclusive dealer editions, and collaborations introduced bold colors, exotic steels, and alternative finishes. The knife earned a reputation not just for durability, but for honesty. It made no attempt to be sleek or fashionable. Instead, it embodied Spyderco’s core design ethos: form follows function, and ergonomy is a requirement.

The arrival of the Manix 2 Salt marked another milestone in the lineage. By pairing the platform with truly corrosion-resistant steels and hardware, Spyderco reaffirmed the Manix’s original mission: reliability under adverse conditions. From urban daily carry to offshore use, the Manix 2 proved adaptable without losing its identity.

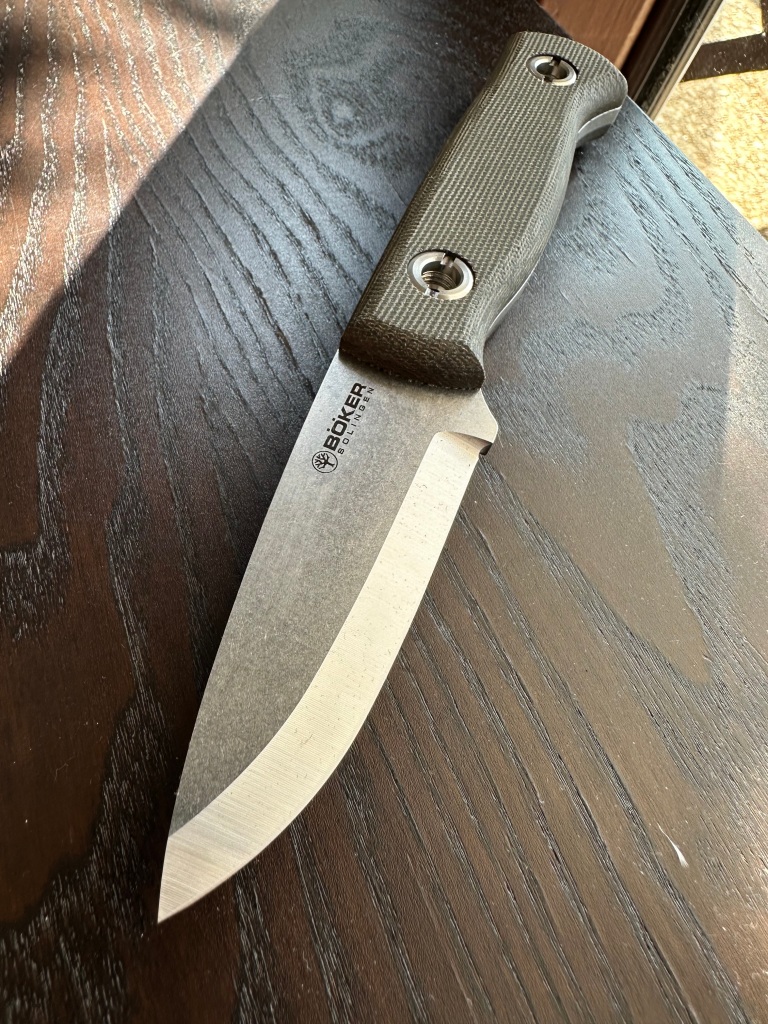

The Spyderco Manix 2 has long been regarded as one of the brand’s most capable folding knives: robust, ergonomic, and unapologetically utilitarian. With the Manix 2 Salt, Spyderco takes that proven platform and adapts it for environments where steel usually fails—saltwater, humidity, sweat, and neglect—without diluting what made the Manix great in the first place.

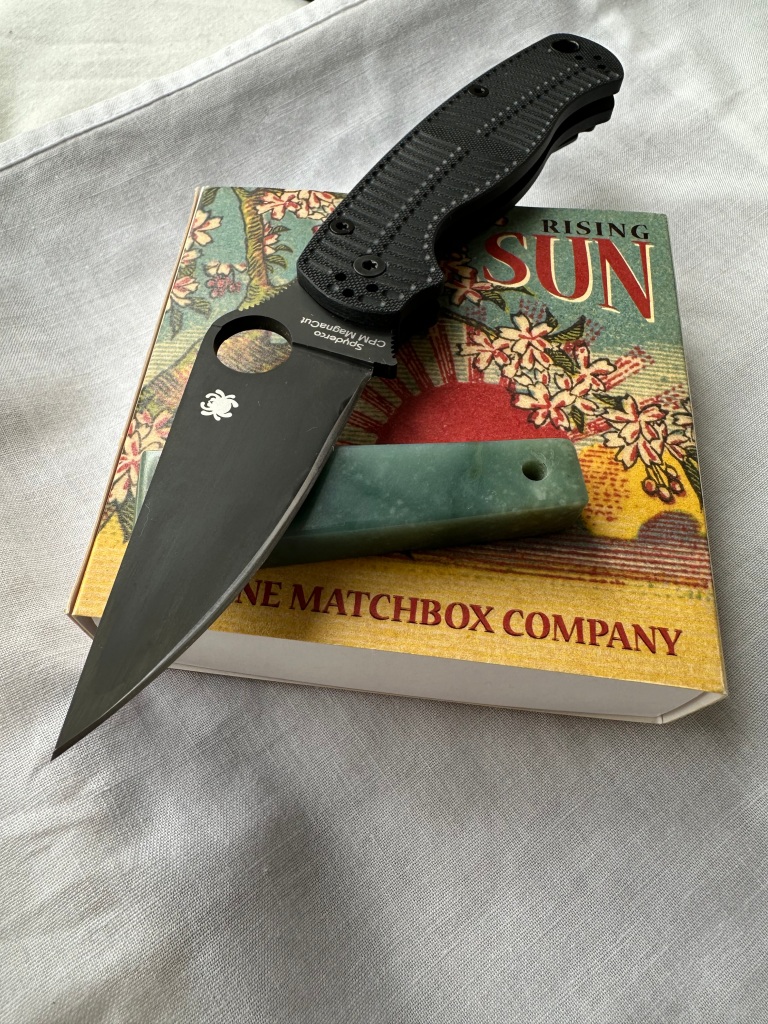

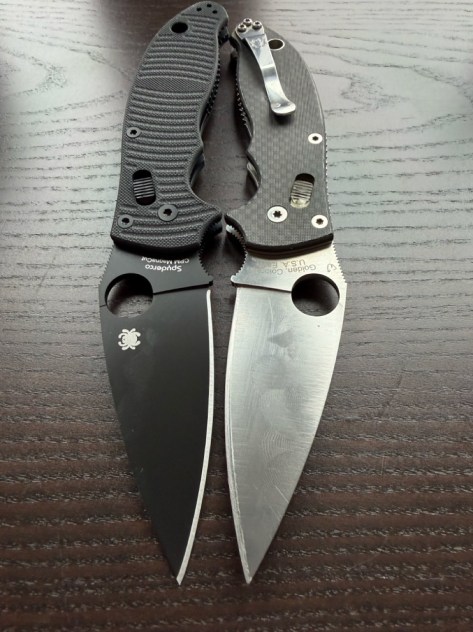

The blade shape remains the familiar Spydie leaf profile, offering excellent belly for slicing, a strong tip, and controlled precision in everyday cutting tasks. What changes everything is the steel. Spyderco’s decision to move the Salt series to CPM MagnaCut is pivotal. MagnaCut delivers an unusually convincing balance: genuine corrosion resistance on par with traditional Salt steels, but with markedly better edge retention and toughness. In practice, this means a blade that shrugs off rust in marine or tropical conditions while cutting like a modern premium steel rather than a compromise.

The Ball Bearing Lock remains one of the Manix 2 Salt’s standout features. Mechanically robust, fully ambidextrous, and secure under load, it inspires confidence in every cut. Out of the box, my lock spring can feel stiff, making disengagement less smooth than some might expect. Fortunately, this is rarely a permanent issue—regular use, or simply a bit of time, tends to ease the action. For those accustomed to the glassy feel of Benchmade’s Axis locks, the initial stiffness may seem pronounced; however, the Manix 2’s single, powerful spring is far stronger and more reliable than the dual Omega springs found in all Axis models, ensuring consistent performance even under demanding conditions.

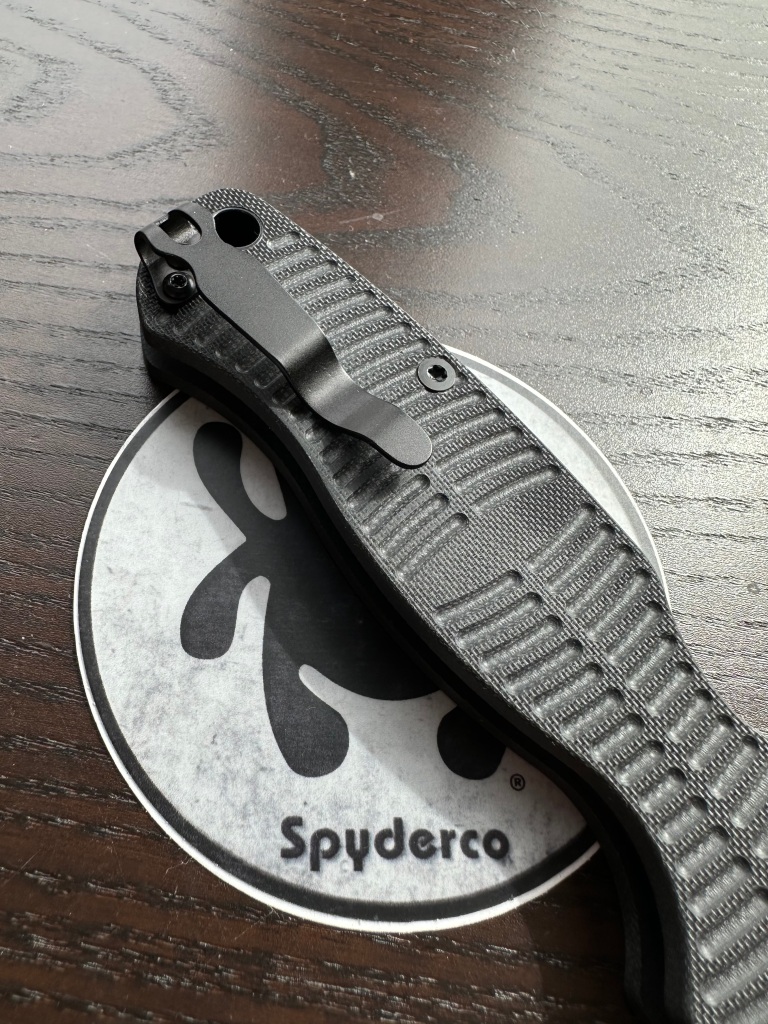

Ergonomically, the Manix 2 Salt truly excels—this is a grip to remember. The G‑10 scales provide a confident, locked-in hold, even in wet conditions, thanks to Spyderco’s signature Caribbean Bi-Directional Texture™. The pronounced finger choil, palm swell, and textured surfaces work in concert to inspire trust, whether your hands are cold, wet, or gloved. This is a knife built to be used, not admired from a distance. Personally, I plan to sand mine slightly to better suit my hand, but even stock, the design is thoughtful: the clip lands on a flat section of the handle, making pocket attachment effortless.

Like in the PM2 Salt, Spyderco’s attention to corrosion resistance extends beyond the blade. Hardware, liners, and clip are all selected with hostile environments in mind. This makes the Manix 2 Salt particularly appealing for sailors, divers, anglers, or anyone living near the sea—users who have learned, often the hard way, that “stainless” rarely means what it promises.

In everyday carry, this Black Pearl of a knife exudes a reassuring sense of overbuilt strength. It is neither the slimmest nor the lightest in its class, yet it makes up for that with unmatched durability, confident grip, and reliable cutting performance. It excels in conditions that quickly reveal the shortcomings of lesser knives, all while maintaining modern efficiency. Folded, it presents as a broad, substantial tool, and clipped in the pocket it occupies noticeable space—its all-black, tactical aesthetic might even intimidate the uninitiated. But once clipped it also disappears on a dark denim. So there is a low profile factor to consider too.

The Manix 2 Salt is ultimately a knife for people who value reliability. It may demand a brief break-in period, and it may never feel delicate—but that is precisely the point. This is a knife you can trust when conditions turn against you, and few compliments matter more than that.