I have enjoyed the Para3 in CPM15V for a week now and after the first pictures, one of my friend Alexandre wrote to me “Looking forward for a convex edge”.

And I have answered to him that I was not in a hurry to do it on this little wonder of modern cutlery. The steel seemed so hard !

But guess what ? What’s bred in the bone will come out in the flesh.

After a week of frustration trying to get any good (spectacular) result on leather and white ceramic….

Some gaffer is on the blade to protect it from any scratches.

My goal is just to “de-shoulder” the edge, to round it for a better leather stropping experience.

It is not rocket science and I’m clumsy and impatient.

So I’m not helped by natural tendencies.

As you can notice the edge near the guard will have less attention.

My friend JD is able to go even but I’m not to his level in making beautiful edges.

But as you can notice it is getting better.

I use a Double Stuff 2 from Spyderco. Mine is old and the glue between the ceramic slate has gone. The diamond slate is not as efficient as some decades ago but it should bite into CPM15V despite its humungous pourcentage of vanadium.

“Since CPM 15V has a high volume (23%) of vanadium carbides (87 HRC) which are harder than the ceramic alumina abrasives. (79 HRC)

That means 23% of the overall microstructure is being pulverized, burnished and adhesively worn to shape rather than cut at the apex.

Over the years I’ve observed a pattern in some folks complaining that these types of steels cannot get very sharp yet the same folks seemingly would refuse to use the abrasive that will cut the remaining 23% of that microstructure cleanly.

I do think that would be fascinating to do a controlled test and look at the differences between the starting sharpness and how that sharpness dies off with cut testing and then compare the loss of sharpness between the two with the same amount of cuts.

I’ve certainly seen this behavior in my personal experience, however, I’ve not documented and shared data publicly.

I’ve mentioned many times that my current favorites for sharpening are the bonded super abrasives rather than the electroplated abrasives. However, there is a cost difference, but in my experience it certainly pays for itself and has better performance.“

Shawn Houston on the Spyderco Forums

First look at the result.

Humm it needs to go one more round.

Ah, I am starting to enjoy the result and how the steel takes the light on the belly of the blade.

Now time to put some white compound polish on the leather.

Again I’m not focusing on getting it sharper it but just to polish the edge and remove any scratches. I want a better geometry like I use to have on the Para3 in M390.

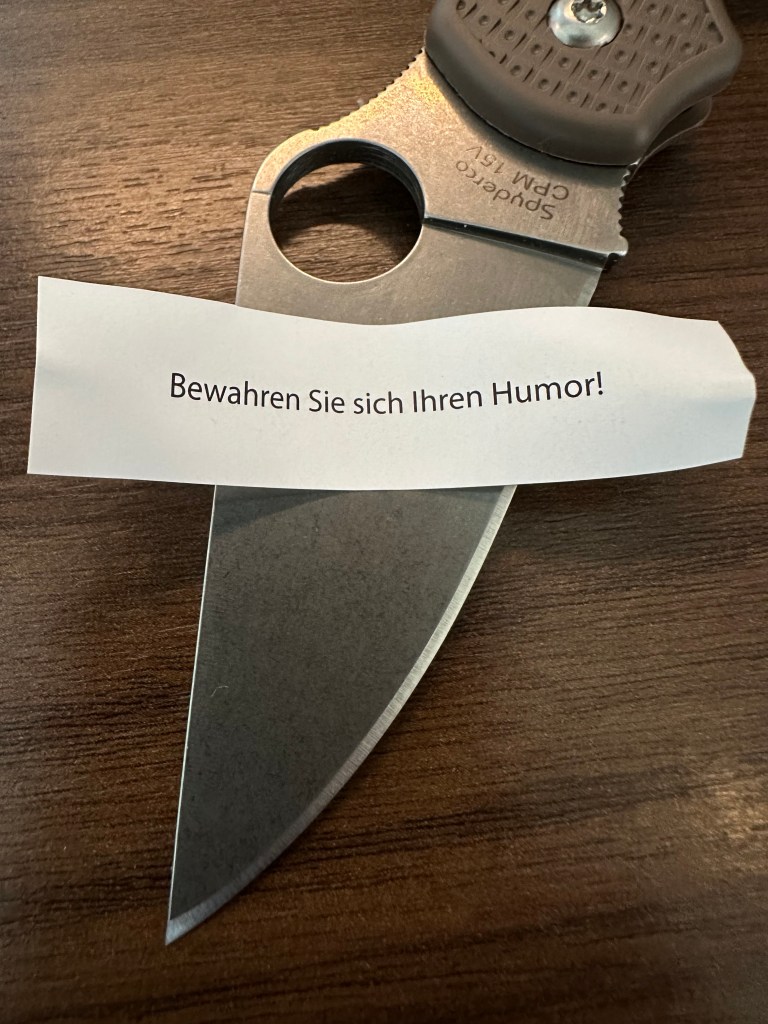

CPM15V does not like to give away its particules.

When I have been able to get mirror edges on D2, 52100 or SPY27 I’m not able to get it on 15V. I need certainly to upgrade my equipement and my game for that.

I will polish it on Jade stone and post better results in the coming weeks.

So far I’m happy with the result. More to come later as 15V is not as easy as I thought to work on (JD adviced me “I think diamond past would help with the stropping. Diamonds or cbn can cut the vanadium carbides, of with this steel has a lot”. Not impossible, especially with diamonds but easy. Maxamet on the other side has proven to be much easier to restore even after catastrophic damages.

But I’m very happy with that Para3 which could be the HoulaHoula (*) of folding knives.

(*) Houlahoula are little birds with big balls and when they land they sing “Houla ! Houla !

On the Spyderco Forums Shawn Houston was kind enough to give some advice about how to get a mirror edge on CPM 15V:

“I recommend skipping the White Ceramic and Jade.

23% of the matrix in the 15V is harder than those abrasives.

A bonded diamond/cBN stone should help with the desired finish.

You deburr the best you can with light alternating passes on the stone. From here, the edge should be sharp enough to cut paper cleanly before moving on. Afterwards, go to a leather strop loaded with 1um Gunny Juice and use alternating edge trailing passes.

This is a good benchmark; keeps the “bite” at the edge without smoothing out the slicing effect. It also helps keep the “grab” at the edge for draw cuts but still keen enough for push cuts.

There’s different kinds of stones. They’re not all created equal.

You can take a diamond stone with the same abrasive and the same grit and it will leave a different surface roughness depending on the construction of the stone.

Yes, there are three major types of bonded stone.

Metallic, resin and vitrified.

There’s even some that are hybrids. However, these are not the same as electroplated diamond abrasives.The work more like regular water stones with better surface finishes.

“Diamond or CBN are the way. You can put a functional edge on 15V with ceramics, but if you’re wanting the real performance 15V has to offer, you need to sharpen with abrasives that will cut the carbides in the steel.”

Wandering_About on the Forums has sum it up.

Shawn Houston was also kind enough to share an AI summary of Instagram Reviews.

“Based on the latest set of reviews, BBB CPM 15V steel demonstrates exceptional performance and user satisfaction.

Performance:

* Excellent edge retention: Maintains a sharp edge for extended periods, even with demanding use (e.g., cutting blackberry roots, heavy use).

* High edge stability: Resistant to chipping and rolling, even with hard use.

* Versatile: Performs well with different edge angles and finishes (from toothy to mirror).

Comparisons:

* Compared to K390, Maxamet, S90V: Sharpening is considered easier than K390 and Maxamet.

* Compared to M4: Sharpening is considered comparable in difficulty to M4.

Key findings:

* Sharpening Ease: Despite its high hardness and carbide content, 15V is surprisingly easy to sharpen. Users report successful sharpening experiences on a variety of tools, from diamond stones and CBN plates to simpler systems. Burr removal is consistently described as effortless.

* Edge Retention and Stability: 15V exhibits excellent edge retention, maintaining sharpness through demanding tasks and heavy use. It also demonstrates high edge stability, showing resistance to chipping and rolling.

* Versatility: The steel is versatile, capable of achieving both aggressive, toothy edges and refined, smooth edges.

* User Enthusiasm: Many users express high levels of satisfaction with 15V, with some even considering it their favorite steel.

Overall:

BBB CPM 15V appears to be a top-tier steel that effectively balances exceptional performance with user-friendly sharpening characteristics. Its combination of edge retention, stability, and ease of use makes it a strong contender for demanding tasks and a highly recommended choice for knife enthusiasts.”

It is light, it is red and it is cute and can skin a wolf or granny’s apple ?

It is light, it is red and it is cute and can skin a wolf or granny’s apple ? “But Grandmother! What big teeth you have,” said Little Red Riding Hood her voice quivering slightly.

“But Grandmother! What big teeth you have,” said Little Red Riding Hood her voice quivering slightly. My own c

My own c SO LIGHT…

SO LIGHT… Deep carry clip and excellent lanyard hole placement.

Deep carry clip and excellent lanyard hole placement.