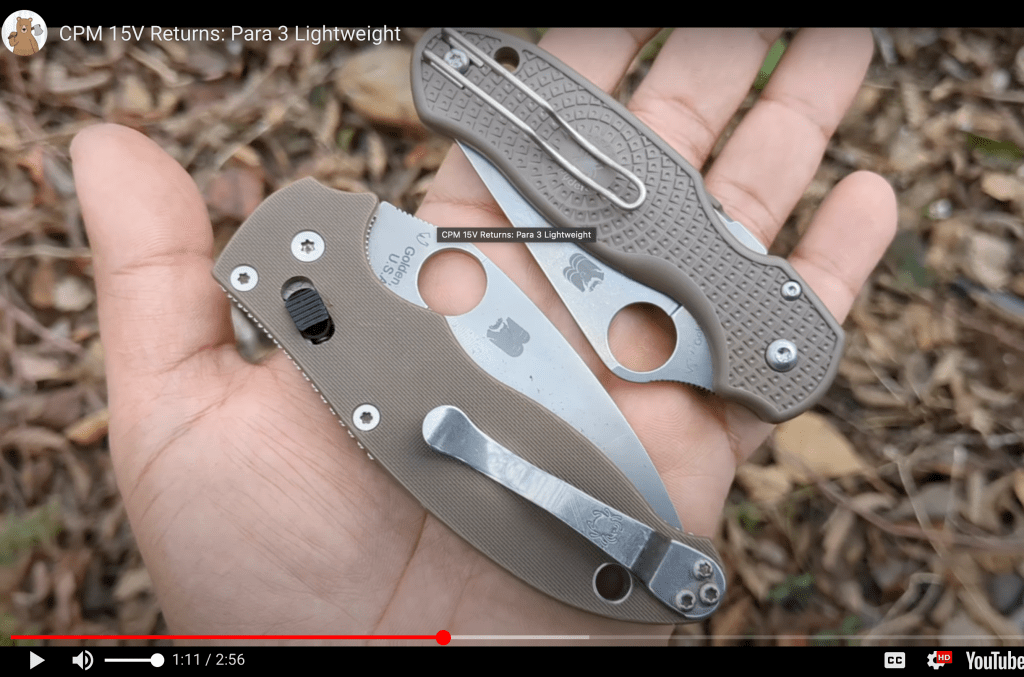

Jumping on the Para® 3 Lightweight Brown CPM® 15V® Sprint Run® wagon was an easy choice after a month of watching our American friends review this new CPM-15V batch.

Following the Manix 2 release two years ago, showcased in the Reveal 11, and a Paramilitary Brown version, here is the chance to test this remarkable steel on a lightweight platform: the Para 3 in brown FRN.

For record CPM 15V is “Boasting almost a 15 percent vanadium content, this remarkable material offers the highest wear resistance of any cold work tool steel available today. The full-flat-ground, satin-finished blade of this knife is further enhanced by a specialized heat-treating protocol developed by acclaimed custom knifemaker Shawn Houston. The result is a blade that offers extreme sharpness and unparalleled edge retention.”

Shawn Houston is known as Big Brown Bear on youtube and his skills in metallurgy and knifemaking as drawn the attention of the Glesser’s family.

In 2018, he has written on the Spyderco Forums that request:

“Sal, Can we get CPM 15v?

“I like this steel. It’s easier to work with then Maxamet and Rex121.

Takes a killer edge and seems to be more stable then s110v.“

Larrin Thomas even answered:

“You guys are crazy. But with Spyderco anything is possible.”

And in 2022 a first Spyderco knife designed by Shawn Houston in 15V with his own heat treat protocol was proposed. Eric’s Manix 2.

“The CPM 15V Sprint run was supposed to be a surprise treat.

Eric wanted to share the CPM 15V with the custom heat treatment I worked on for my folder design.

His idea was to use a standard model so people can get their hands on the steel. Which I thought was really, REALLY cool of him to do that.

Working with Crucible and Niagara Specialty Metal we were able to select a specific melt of the CPM 15V that would respond best to this specially developed custom heat treatment.

So, Eric and Sal really went all the way on this, no other production knife company on the planet would do something like this. Eric and Sal are one of a kind.

You guys need to understand this is very unique having actual knife/steel/sharpening/edge people running a knife company that can cater to enthusiasts.

Originally, I was given options for different handle scales for the Manix but the most important priority was to get the CPM 15V Manix out as soon as possible so it didn’t make any sense to use exotic scale materials.

G10 is a great material to work with and brown g10 was selected because “Big Brown Bear” aka Triplebhandmade. (Me)

I am aware as many others that brown g10 is not unique to this model.

But the color of the handle scales and the handle scale material are irrelevant to edge performance and the most important priority was getting this out to you guys as soon as possible.

Looks like the price is great too, if we used carbon fiber etc cost would have been higher.

So, I hope you guys can respect that.

The folder collaboration design was being pushed back due to production capacity being completely full at Golden.

Please understand that I’ve been very persistent at wanting the knife made in Golden come **** or high water; I would wait until the stars burned out.

Spyderco has been very busy increasing the size of their golden factory to meet the insane demand of the current knife industry after the global pandemic.

Keep in mind, when a new product comes through the factory, they have to train the staff on how to make them, and what the best procedures are for creating that specific model in high volume with maximum efficiency. So, there is hidden effort when new designs come through at Spyderco.

Folks need to remember if we want this folder made in Golden (my favorite factory) we have to be patient.

My dream is to have a Golden folder we can all experience together.

I’ve gotten a chance to meet the people from the Golden factory I must say I’m even more excited about the idea of it being made in Golden. I’ve talked to the people that do grinding and heat treatment and there’s just something special about being able to talk to the folks that make your collaboration knife design.

So, I keep pretty quiet about the folder because I don’t feel it’s necessary to see get people excited about something that doesn’t have a clearly set date of exactly when it can be expected and I don’t want to put any undue pressure on Spyderco because they’ve been working very very hard over the past couple years to get things that sometimes people take for granted and expect to magically appear on the shelves to buy.

While I haven’t been posting in this thread everyday, I really appreciate you guys making sure to let Spyderco know this is something you want.

So, thanks for always updating this thread and talking about it on social media.I really think you guys will like this knife and I can’t wait to get one in my pocket one day.

-Shawn“

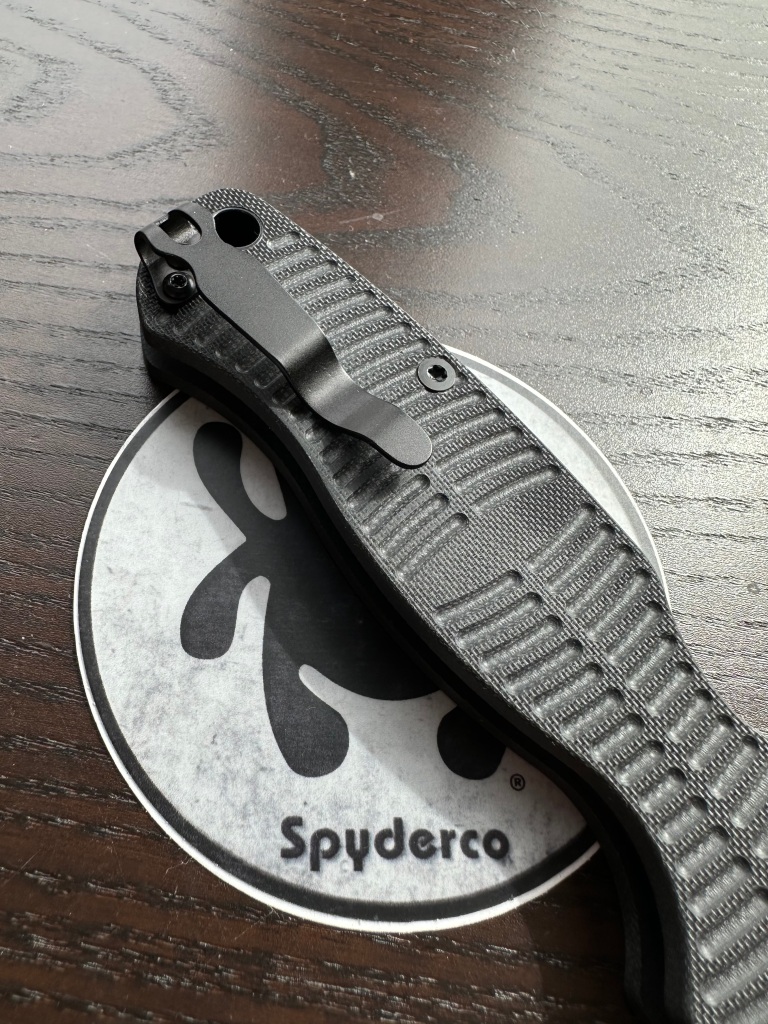

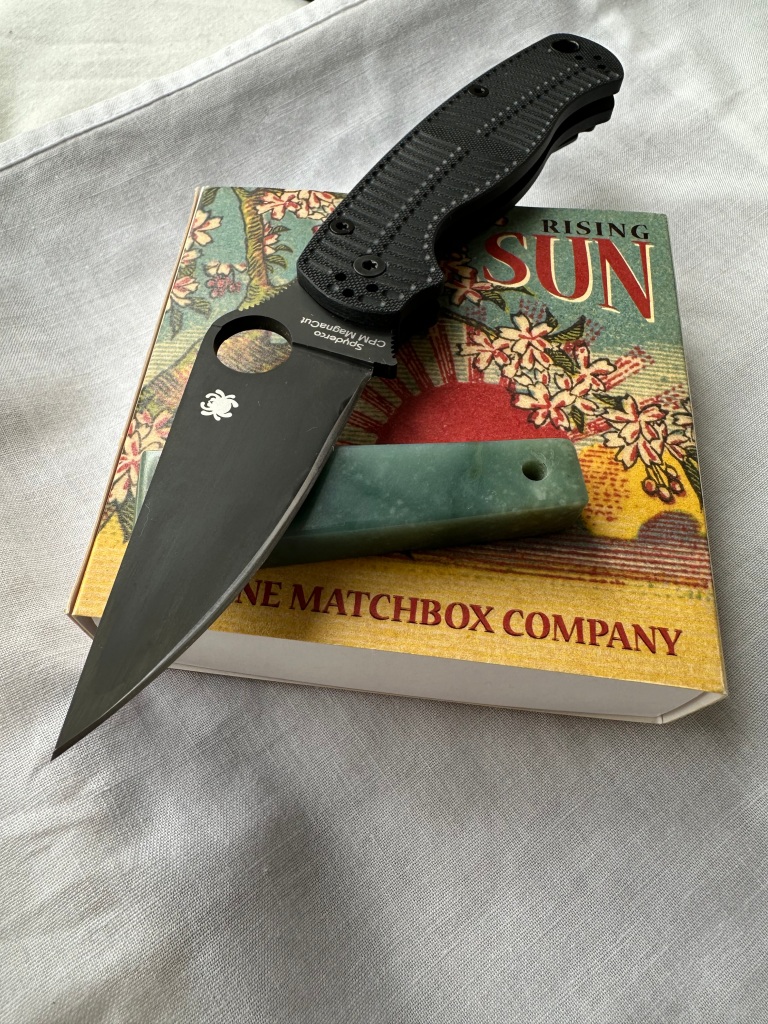

Now this is new batch including Microjimbo, Yojumbo, Yojimbo2, Native, Military 2, Para3 G10 and Para3 Lightweight.

Like all its brothers and sisters it boast the BBB logo proving that the blade has followed Shawn Houston heat treatment.

In his excellent vidéo Shawn share his first impressions and also check the hardness of his Para3 and the result is 65.4 HRC ! Impressive !

Framed from his video: he performed five separate hardness tests just to be sure. It’s well known that Shawn Houston’s special heat treatment — refined over years and tested by renowned professionals — brings out the quintessence of CPM-15V, elevating its performance to exceptional levels.

“Well, most heat treatment protocols are for tooling, like the ones in datasheets — not really optimized for things like edge stability.”

— Shawn Houston, on his own heat treatment

In practical tests, Pete from the Cedric and Ada Gear and Outdoors was able to cut through a rope 2,000 times without compromising the edge.

The action on my new Para 3 is perfectly smooth. I notice a little lock sticking but this is not an issue in my book.

And smooth enough that nothing unscrews on it — the blade closes like glass, effortlessly and precisely.

My Para 3 arrived perfectly centered, but with some burrs on the scales.

(A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process.)

You can feel these tiny imperfections under your finger along the FRN edges.

I have “deburr” it with some diamonds rod. Nothing fancy but now the handle is fine. I don’t remember having that issue on my previous Para 3 review.

The edge is even.

I don’t see myself working on a convex edge on this one. Not for the moment.

The sharpness is high and that blade is a hair popping sharp razor right out of the box.

I have already cut my self with its very pointy point. My Para 3 is baptized !

Now it is truly mind.

It is said that CPM-15V loves leather for a crispy edge.

(S90V or M398 for example don’t care about stropping…)

I’m curious how its 68 grams will compete with my Maxamet Para 3 G10 (98 grams) — sturdy yet smooth as velvet.

According to Spyderco:

“The term ‘lightweight,’ or the use of injection-molded handle components on a Spyderco folder, isn’t just about how the knife tips the scale. It’s about taking full advantage of the remarkable properties of FRN and FRCP, as well as our decades of experience as an industry leader in their use.”

So yes, this is a “light” saber.

The edge appears ground thinner than on the notoriously brittle Maxamet blade. Both blades receive special attention: the spine is smooth under the thumb, and the edges are expertly bevelled.

The chance to have such a steel on a lightweight folder would make it a great hunting knife like the Michael Walker ZDP-189 was in his days.

The game’s fur is very abbrasive. CPM-15V could be even stronger than ZDP189 on the joints, more permissive.

Ericasedc has made a video about that:

She seems really happy with her Para 3 since she has received it. You can see all the videos she has made on her channel about the Para 3 15V.

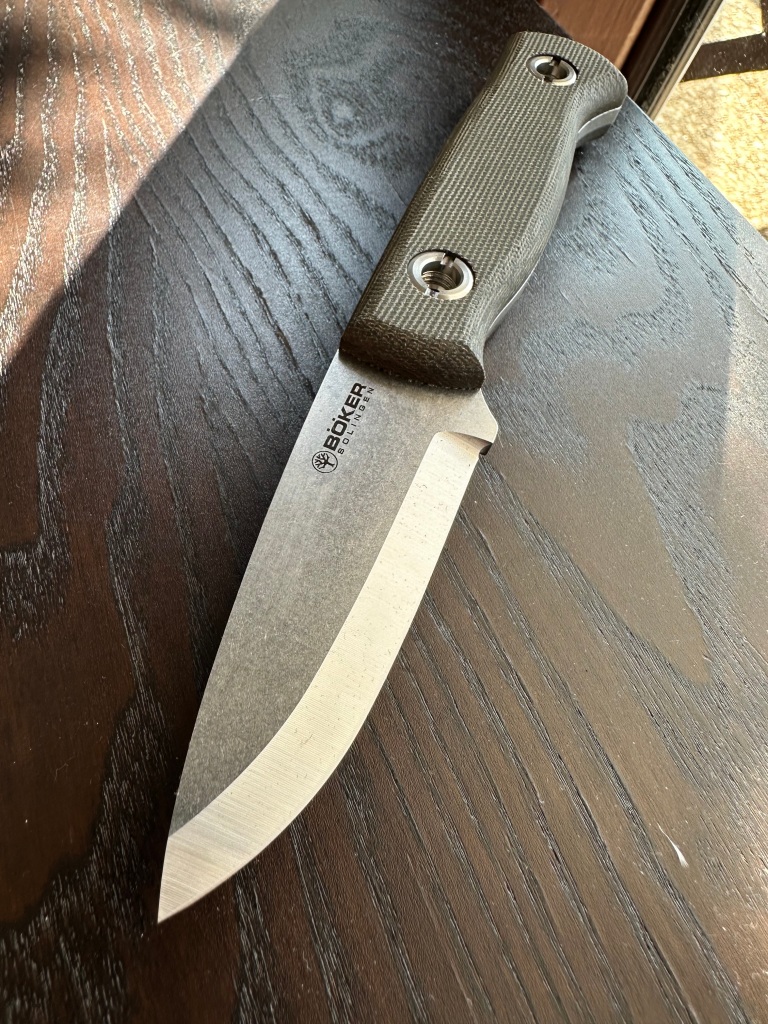

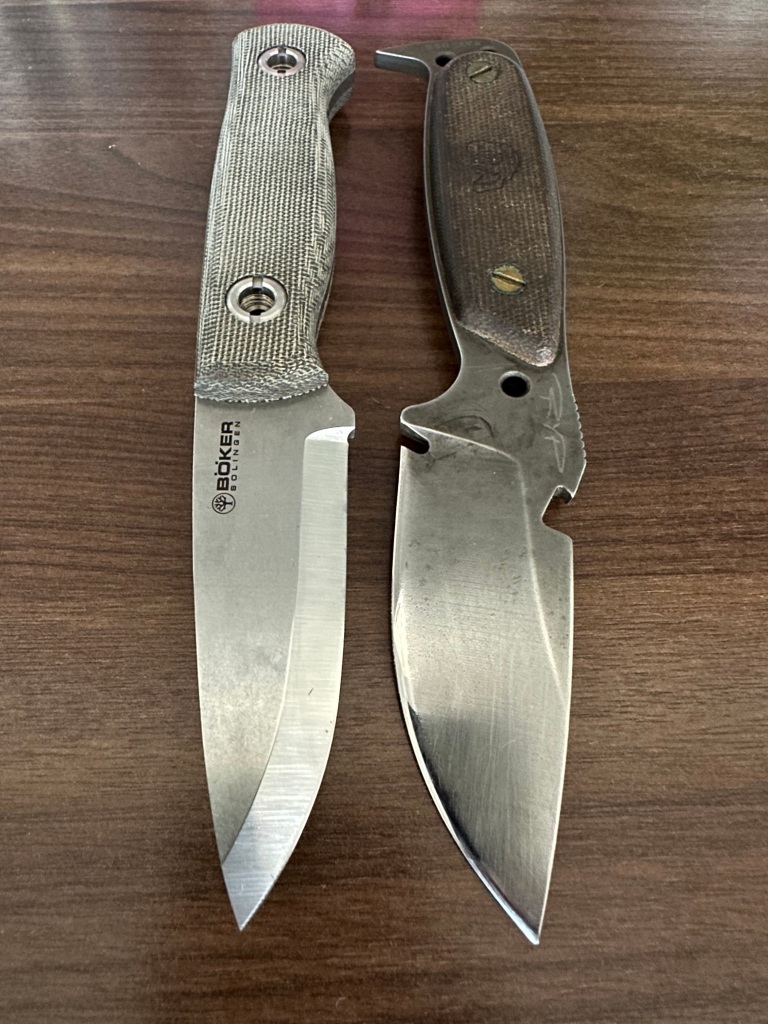

Anyway, going in the woods equipped with a Tenacious CPM M4 and a Para 3 in 15V would be a great combo nowadays.

Now that I can carry the mighty CPM-15V steel in my pocket, I’m eager to test its performance over the long run. Stay tuned for updates on this page or in another chapter.

Having a featherweight folder equipped with such a formidable blade and steel is uncanny — it packs remarkable power in a pocket-sized package. I still remember fitting the Maxamet blade on my red FRN Para 3 just to experience that sensation of a powerful engine on a lightweight platform.

This Para 3 Sprint Run is already a triumph, offering the chance to experience a remarkable steel crafted by passionate knifeaholics.

As mentioned, I have no intention of convexing the edge for now — I’m trusting Shawn’s expertise. Unlike AEB-L, which can be thinned while remaining strong, CPM-15V is packed with carbides, so I’ll stick with the angle specified by Spyderco and Shawn, which is already thinner than Maxamet.

But now, the real fun begins: testing!

Spoiler: the combination of geometry and steel makes it an excellent whittler — the blade cuts deep, and the wood feels incredibly smooth under the cut.

Final word of this review are from Shawn Houston who was quoting and answering to Todd from Scienceofsharp.com about 15V (as Todd’s goal is to increase our understanding of the role of carbides in cutting performance and how different sharpening techniques “interact” with the carbide):

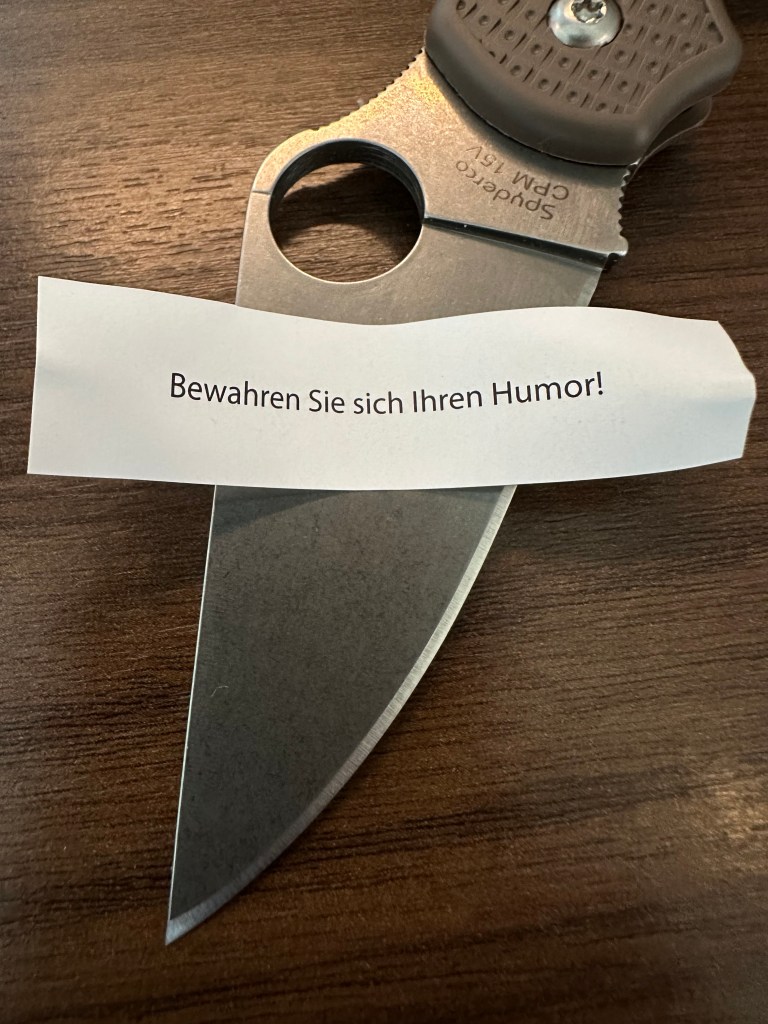

““tremendous pleasure in using an extremely sharp knife or tool (and satisfaction when you have sharpened it yourself). Even though it is often a fleeting experience”

That’s the “idée fixe” of it all.

The little smile and feeling of elation when the edge lasers through material with zero effort.

The stones, geometries, steels, heat treatments and the techniques.

Chasing those fleeting moments of joy with high performance and riding the line between madness and clarity in trying to understand at the most intricate levels how it all really works.

An insatiable quest.“

“The Edge is a Ghost. Always changing. Dying (dulling) being reborn (sharpened) split personality (angles and geometry changing).

Think of the edge as gas in a vehicle. It runs out of gas and you put in more gas. We provide the format, materials, design for use, variety to avoid boredom and create interest, but the edge is your creation. The result of your understanding, education, experience and practice.”

Sal

“CPM 15V is a very difficult steel to manufacturer, so it may not always be available in the future.

Crucible Industries LLC went to great lengths to produce the steel, it puts a great amount of wear and tear on the ceramic refractory designed to hold the super heated liquid steel during melting. This is necessary to dissolve the vanadium carbides to the very fine sizes that we see in the finished product.

It’s quite a marvel that’s not often appreciated.

15V is basically the commercial limit for how much carbon and vandium they can get in a steel for production sizes batches.

The benefits of this to the end user combined with excellent heat treatment is a enjoyable, lasting cutting experience that also touches up at the edge nicely with proper abrasives and sharpening experience.”

Shawn Houston on Spyderco Forums