Disclaimer: This knife was supplied at no cost by Golden as part of their brand ambassador program. Spyderco’s decision to include this publication is appreciated, though the review that follows remains independent and unbiased.

This is my first glimpse at the middle Brother of the SLIPIT™, the Metropolitan.

Made in Maniago. It is an Italian Spyderco.

Un altro piccolo grande coltello !

It is the second Spyderco Slipjoint in M398 after the Roadie XL which I use a lot !

It is made in Maniago like my Heinnie Urban and it is a pure Sal Glesser design.

The blade comes razor-sharp straight out of the box. The factory edge is excellent, though I know it can be refined just a touch on leather. It’s a very thin grind—thinner even than on my Roadie XL. While M398 isn’t as leather-friendly as SPY27, it can still be brought to a high polish, as I managed with my Roadie XL after breaking its tip.

Being slightly longer than the Urban, the Metro’s handle comfortably fits four fingers when using the choil. This choil also adds an important safety feature, preventing accidental closure on your fingers. The choil-hump combinaison—acts like a guard, directing cutting force straight into the blade while relieving stress on the handle and pivot.

“Metro In the Middle” pictured: the G10 SPY27 UKPK “Golden Child”, the Metro and the Heinnie G10 S90V Urban.

To quote my friend Wayne Thomas Heywood Adamson: “So now we have a middle ground between the UKPK and the Urban. I was surprised when the Urban shrank in size but that was clearly now to make room for the Metropolitan.”

(Made in Golden – Maniago – Maniago.)

The 68mm Metro’s blade thickness measures 3 mm at the spine, with a full flat grind in a leaf-shaped profile. By comparison, the longer UKPK “Golden Child” comes in at just 2.5 mm, which makes it the undisputed king of SlipIt designs. That said, opting for a slightly thicker blade in M398 is a sound choice. M398 is not known for its toughness—certainly less forgiving than Spyderco’s in-house CPM SPY27 alloy—so the added thickness provides welcome reinforcement.

The S90V Urban is 2,9mm !

And the Roadie XL is 2,8mm

Making the Metropolitan the thicker of the wild bunch !

By an hair !

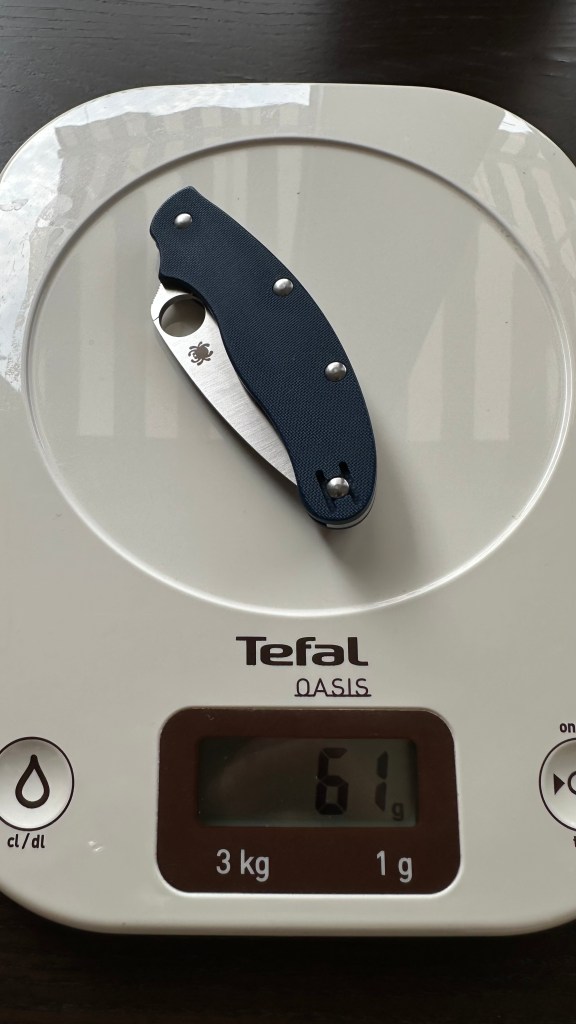

Now about the weight…

At 51 grammes it is really light in the pocket.

The action is very good. It is as strong as my Urban and UKPK. perhaps a bit less hard to close but this is not really an issue.

I have noticed the Metro’s back is a full spacer/spring construction like a G10 version (when the UKPK FRN Salt is not for example.)

It does not share the same “fork” spring of the UKPK but the same slipjoint mechanism as the Urban.

You can feel the spacer moving up when closing.

So what can we expected from this Metropolitan compared to its siblings?

A little more room for your fingers. The Urban and the Squeak are three fingers knives, the Metro and UKPK are four fingers.

This is also an opportunity to showcase M398 in a high, full-flat-ground, thin blade. The Roadie XL’s narrower profile already favors cutting efficiency, and the Metro builds on that. In terms of edge retention, M398 belongs in the same category as S90V—a steel I know well from my Urban model, where securing an exclusive sprint run was a real challenge. With the Metro, however, M398 is now part of the regular production lineup, offering users a true “super stainless” steel in an accessible package. But beware M398 does not like torsions, like my Walker in ZDP189 which has been able to survive all those years.

The Metropolitan could really be a major upgrade for my Italian Hares Hunter in Tuscany. For the record, skinning game—especially dealing with hair full of sand and dirt—puts a significant challenge on edge retention. Hunters typically don’t use their knives for woodcraft; their main task is working on hares and similar game. In that context, a blade of 68mm in M398 could offer a real advantage.

The Metropolitan—easy to carry, legal in many countries, and made of stainless steel—could be the perfect hunter’s SlipIt, which is great news for many of my friends.

So eventually, we left our chairs early to gather around tables where Ted had displayed all the knives. It was time for intense exchange and card writing.

So eventually, we left our chairs early to gather around tables where Ted had displayed all the knives. It was time for intense exchange and card writing.

Picture of the Custom original Wolf Mouse. Found on

Picture of the Custom original Wolf Mouse. Found on