This is a first glimpse review with Paul Alexander explanation at the end.

So I got the knife for less than an hour in my hand and this is just what passed through my mind just playing with it during photographies.

So it will be followed by more in situ testing. I remember Paul Alexander’s proto at the Minimeet and the fact that he is an engineer in automotive and not a knifemaker. I liked that. Sal Glesser is an inventor and he loves engineering, so it was logical for him to welcome some bold new designs coming out of the bladeshows sphere.

Oh, the Sliverax !! She’s a looker. Pure beauty and this is not only in the eye of the beholder. Perfection of the grind, the bolt starship design. I’m whittling while I’m holding her. She got a wasp shape, something of a spaceship, created for performance…

But the first thing I have noticed is how light (94 grammes) she felt and how well balanced she was. The sweet point is just behind the pivot making the Sliverax alive. Also the blade got that angle with the handle which reminded me Ed Schempp’s design: once open all the back of the knife forms a bow. It’s ready to cut and really ergonomic.

The Sliverax got that kind of wasp shape very biological, organical and natural in her lines.

This is pure a full flat grind with a perfect finish. Taishung at their best again. No jimping, no tactical frills: clean and pure lines.

And once closed she’s very much like a Yin and Yang symbol.

This very thin handle is possible thanks to the Compression Lock which as the center of the design. It seems like an improved version with two pins which makes it feel very solid. Also two bronze phosphorous cages for the ball bearing is a very nice improvement compared to the Advocate or Mantra 2 pivots.

Quoting Paul Alexander on the Spyderco Forums:

“So, the compression lock is by far my favorite locking mechanism, and once I felt I had a good handle on how to implement the lock in a sound manner, I pretty quickly started to consider incorporating a flipper mechanism. As an aside, I have a bit of a love/hate relationship with flippers. On the love side, I do really enjoy the almost instantaneous deployment you get with a good flipping mechanism; and somehow, incessant flipping never gets old… at least not for me, the wife and kids get understandably annoyed after a while. On the hate side, I’m not a fan of the protrusion flipper tabs usually entail. They can be cumbersome in pocket (I really do spend a lot of time considering the closed form of my designs, and while actual use is paramount, my personal knives probably spend a fair bit more time in my pocket than in my hand… sigh, office life). Plus, the tab can almost ruin the knife aesthetic if you’re going for really clean, svelte lines for a particular design.

The Sliverax mechanism was the first workable version of a compression lock flipper I came up with, and it’s pretty straight forward. The flipper tab is just an extension on the tang, wrapping around the stop pin to get the tab into a location that gives it the right amount of leverage and generates a big enough moment to open reliably. This ends up creating a detail that looks a lot like a portion of an internal stop pin track just inboard of the flipper tab, but the cut out is further away from the pivot than a full internal stop configuration, to keep the blade as robust as possible. And that’s about it. I’ve got 2 or 3 other flipper incarnations I’m trying to work into newer designs, but really at their heart they are all fairly similar, you have to have certain features and components to make it functional, and then you come up with design inversions that better integrate into your target package.

I also believe in simplicity and elegance in a design whenever possible, so I try and not get overly intricate or complex, and start forcing extra elements or components into a knife. We’re already putting bearings in these things, and that’s probably on the upper end of what I consider reasonable for what is supposed to be a ‘basic’ hand tool. In the end, bearings are still a far sight better than most opening assist mechanisms out there, and they do provide consistent, smooth flipping action in a pretty cost efficient manner.”

The CompLock makes it also a breeze to fire. It flips open with fast. My detent is OK.

The handle shape makes it also perfect for classical hole opening. This is a real pleasure to be able and to have access to the Spyderhole even with the left hand.

I can open it like my Paramillies: with a middle finger opening.

The texture of the carbonfiber/g10 handle is perfect in my book. It won’t tear my pocket. And the wire clip install is one of my favorite. Again It look a lot like the clip mounted on the Ed Schempp bowie. Both knives are cousin:

So as much as I love my Bowie, the Sliverax is a love at first sight. But she’s much lighter in my hand and in my pocket and the blade is actually thicker 3,6mm vs 2,5mm for the Bowie.

So the Sliverax feels like a dancer in my hands but the blade shape is oriented toward reliability in cutting and using as a tool. Sure, there is no play vertical or lateral what so ever.

But the funniest and amazing particularity of Paul Alexander’s design is the way the edge is actually longer than the blade. The edge goes under the pivot and stops at 2mm from the flipper.

This design gives a lot of edge for a light EDC. On a portable solution we are always looking for the maximum of performance and here, for once, the cutting edge has been generously thought! This is a first for me.

The Sliverax seems also easy to clean thanks to its open construction. Really a serious tool for going in the wild or to be rinse in the kitchen sink. This is not a safe queen but a folder to be used.

Spyderco links is here.

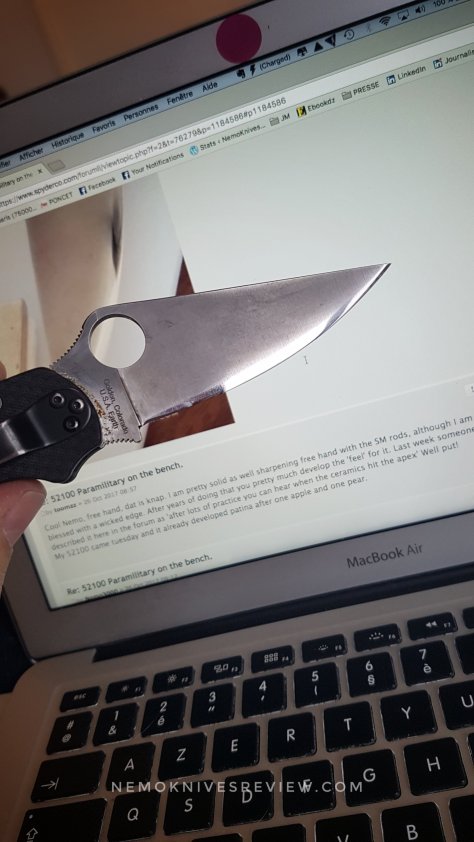

So far here are the pictures:

And some comparaison with other knives…

And yes she cut right through the plastic bottle but with her factory edge.

And you can notice how the spine is chanfered too.

I have asked Paul Alexander the story behind his design.

Here is his answer:

“As far as design intent, I was definitely going for a comfortable, average use EDC knife. I’m a huge fan of negative blade angles and the less fatiguing loads it puts on the users wrist and forearm. I personally think of this design in two different ways, it’s either a modified wharncliffe with a slightly negative blade angle or a thin leaf blade with a much more pronounced negative blade angle, it really comes down to how you approach the material to be cut with the edge/tip and what task you’d like to perform.

It was definitely not a design focusing on use on a cutting board or other flat backing surface (the negative blade angle limits that quite a bit, as does the flipper), but more for free cutting tasks such as breaking down cardboard, opening plastic clam-shell containers, opening packages, shaving/stripping the surface of various wood stock, etc.; and I think it performs tasks like this quite capably.

It’s been years since the design was submitted to Spyderco, but at the time making a compression lock flipper was a novel feature which I was trying to accomplish. I also prefer a generous swell to the butt of the handle to fill the palm. I like to secure the grip of almost all of my designs by primarily pinching it between the thumb and index finger in a saber grip, with the bulbous handle allowing the rest of your fingers to rather loosely wrap around it and be used to subtly direct the blade pitch and rotation when needed, but also be readily gripped much more tightly when necessary. “

Time to start gently to convex that beautiful blade…. And here is the link to that.

There is a lot of matter to remove and by hand, it takes some time.

There is a lot of matter to remove and by hand, it takes some time.