The title could have been the “Poor Man Woodlore” but it would have not reflect the quality of this N°10 SFK Bushcraft knife. For twenty years now I have follow with interest the long walk of Ray Mears in the wood. Producing an elegant fixed blade to make some magic of barks, sticks and leaves. First time I have seen him using his knife, I thought to myslef: “Who is this guy who walks in the countryside with a fixed blade in his pocket…” This is where my interest for the man and the tool has started.

I was already using a Hello Scandi grind knife back on those days with cladded carbon steel.

Bushcraft is a childhoold adventure dream. It mixes Tarzan, Rambo and all those scouts and indian stories. You can go playing in the woods with your favorite new sharp toys, creating things like bows, arrows, huts, shelters… I was doing bushcraft with my uncle Guy back in the 70’s. He was using a sturdy slipjoint german knife we called a “Canif” (k-nife) and soon I was allowed to bring my own fixed blade knife. Later, when I was 11, I was really into it after investing all my money in a Glock Feldmesser 78 which was a game changer for me: I was able to chop wood !! Any way, a fixed blade was always my best friend in the wood and I have often asked for a sheath I could pocket easily. Don’t laugh but I still got my Rambo II knife… perhaps the subject of another article. Anyway here a picture:

Ok back to the topic: Casström No.10 Swedish Forest Knife.

Casström is a manufacturer and distributor of top quality knives and outdoor equipment. They got all a collection of knives and some beauties for bushcrafter. They are famous for having a survival knife developed with survival expert Lars Fält an old friend of Ray Mears. But I was not interested in that collaboration. Why ? because I was looking for a smaller knife. My attention turned to the N°10 with its 10cm long blade compared to the Lars Fält with it 11,5 cm blade.

I add noticed they were selling Second Knives in their site. It sounds great to me since I got a great experience with Second knives in the UKBushcrafter sale some years ago.

So I have contacted them explain to them that an handle or cosmetic was not an issue as far as the blade was perfect for the review. Gently they have decided to send me a perfect knife instead of a second and that for the initial price. Very nice gesture.

From their site we can learn that it was designed a multipurpose knife for hunting, bushcraft and general use in the great outdoors. The blade is 10cm long and made using 3.8mm thick Austrian made O2 high carbon tool steel (Böhler K720) and heat treated to achieve a hardness of 58-60 HRC. The knife is ground with a shaving sharp flat Scandinavian grind and have a satin finish… and it’s true, it was shaving sharp right out of the box.

What I had noticed on the pictures of N°10 knife was the handle: it’s not straight.

Immediately after holding it for the first time, it was love at first palm ! The handle is so well thought after, it literally makes love with your hand. It’s like Ed Schempp or Paul Alexander knives designs, straight lines are not our friends, curves are our friends.

You see where you pinky can wrapped itself ? It is so confortable !

You can also see the black liners between the handle scales and steel to enhance durability over time. The site explains also that the wood has been treated with a traditional Scandinavian linseed oil based varnish.

The knife comes with a sturdy welted sheath made from cognac brown 3mm vegetable tanned full-grain leather. The sheath features an extra wide belt loop, a fluid draining hole and a lanyard hole. All based have been covered. The sheath looks sturdy but I was happy to apply some bee wax and jojoba in it to smooth it a little.

About the steel: Böhler Tool Steel K720 is a very tough and strong oil hardened high carbon tool steel also known as O2 : C. 0.9%, Si. 0.25%, Mn. 2.0%, Cr. 0.35% V. 0.1% (HRC 58-60)

Compared to

O1 Tool Steel. C 0,85% Si 0.50%Mn 1.00% Cr 0.60% Ni 0.30% W 0.40% V 0.30% Cu 0.25% P 0.03% S 0.03%

They are brothers in the tool steel department as “Bushcrafters generally don’t seek the characteristics of stainless over the performance of high-carbon edge retention, and is why traditional Bushcraft knives are produced using tool steel for their blades.” Spyderco Catalog.

Compared to the UKbushcrafter in G10 they also brother in the same department.

The main difference between them is the weight; 68 grams lighter for the N°10. G10 is heavier and more dense than oak. I do prefer also the wood handle which feels less slippery than G10 when my hands are wet.

The sheath also is less bulky that on the UK Buscrafter which feels like a bigger knife all in all.

But compared to the original Woodlore we are in the same game: same length , same weight, same kind of steel, same grind… Which makes a great alternative with a very clever handle at a fraction of the price.

Really, Casström people are entering the bushcraft game with great products at a very nice price. The N°10 made in Sweden (*) can be found around 120 euros with international shipping and you can compare to the 460 euros of the last Ray Mears design made in the UK. Alternatives are good.

Time to test the knife now. More to come soon.

* “The knives are manufactured predominantly in Spain, but with design, material selection, final finish and quality control here in Sweden. The finish is very high in relation to the price and materials used as you can see. The wooden handles we make are close to custom grade.” David Cassini Bäckström — Casström AB

I had ordered a titanium deep carry clip for my

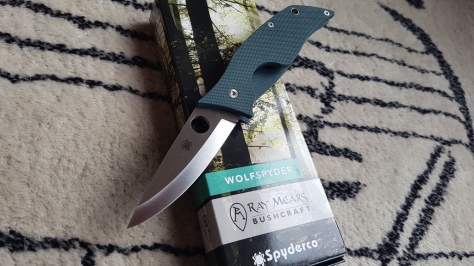

I had ordered a titanium deep carry clip for my  So here it goes !

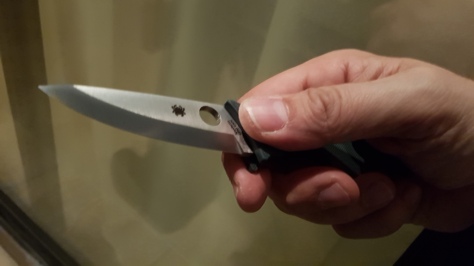

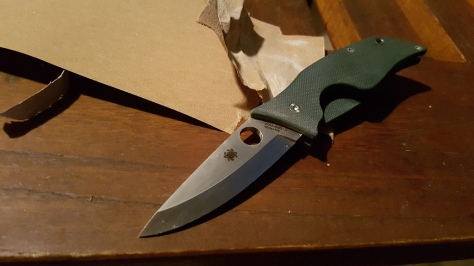

So here it goes !  I’m always amazed at how thick the blade is and how solid this little folder is after one year without real maintenance. I have found the scandi S30V quite easy to maintain razor sharp and to my surprise it is easy to keep that way without any convexing and losing the “zero ground” scandi edge. But the best thing about the Wolfspyder is how hard

I’m always amazed at how thick the blade is and how solid this little folder is after one year without real maintenance. I have found the scandi S30V quite easy to maintain razor sharp and to my surprise it is easy to keep that way without any convexing and losing the “zero ground” scandi edge. But the best thing about the Wolfspyder is how hard Easy to carry and easy to reach in the pocket. This one will be in my pocket for a trip in Norway very soon ! The Scandi ground little big knife in Scandinavian territory !

Easy to carry and easy to reach in the pocket. This one will be in my pocket for a trip in Norway very soon ! The Scandi ground little big knife in Scandinavian territory !

O

O