Spyderco Urban, Squeak and UKPK family is one of the most addictive slipjoint proposition in the modern world. I have already written about them in this blog. The UKPK Salt is simply one of the best modern folder available nowadays. The Squeak is totally sheeple friendly and of course the Urban made for the city and to be carry everywhere but on the airlines.

Spyderco’s description:

“This Exclusive version of the Spyderco Urban™ was manufactured specifically for Heinnie Haynes (heinnie.com) and is available only through their sales channels. Originally introduced in 2009 and later discontinued, the Urban remains a cult classic among devoted fans of Spyderco’s non-locking, one-hand-opening, clip-carried SLIPIT™ knives. This distinctive expression of it showcases a leaf-shaped blade crafted from premium CPM® S90V® particle metallurgy stainless steel. The PlainEdge™ blade is full-flat ground for exceptional edge geometry and is proudly laser engraved with the Heinnie Haynes logo.Not to be outdone, the handle of this knife features distinctive red G-10 scales with a non-slip peel-ply texture. They complement the jimping (textured grooves) on the blade’s thumb ramp and index-finger choil to ensure a positive grip and outstanding control during use. A reversible deep-pocket wire clip provides a choice of left or right-side tip-up carry, making every aspect of the design completely ambidextrous.”

This Red One is my third Urban. The first one was in K390, the second one was in AEBL and named Cappucino. All of them has been pushed out of my pocket because of the greatness of the UKPK Salt in LC200N.

Anyway they all have been great companion during my UK travels as they are totally legal: non locking under 3 inches blade (76mm)…

Eventually I have been looking for a G10 version with a full stainless steel back spacer and I have found the Heinnie Haynes exclusive version available on their site. It is not a cheap knife be aware of that but it oozes quality on paper and in the hand.

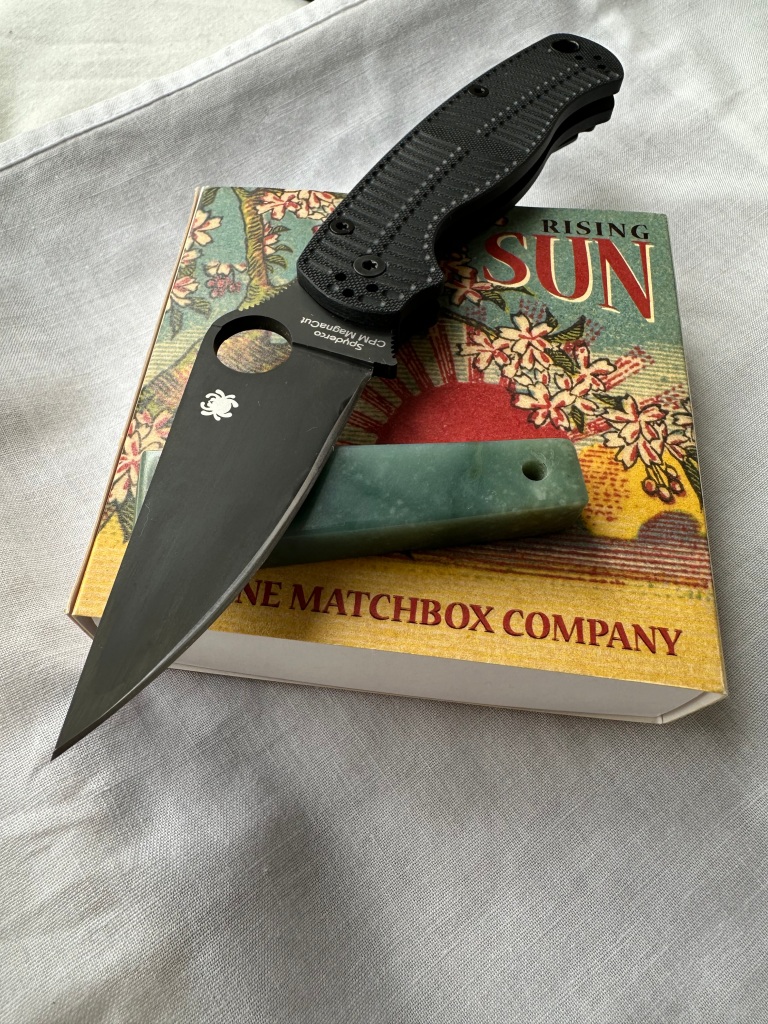

First thing first, this Urban got a CPM S90 V blade, the same found on the Proficient Bushcraft knife. S90V was known before as CPM420V and it is still one of Sal Glesser favorite steel ever to be produced by Crucible.

S90V is known for its incredible edge retention and in the last 25 years of using it, I can tell you this one can be a bear to resharpen. Diamonds are its best friends and even then it needs a lot of white ceramic time and stropping… Compared to non stainless super steel like Maxamet it can be really tedious to get really sharp. But one it is sharp, its working edge seems to stay forever on.

This is exactly the opposite of my previous experience with Cappucino my AEB-L Urban. This one was strong and a breeze to keep razor but it was back to butter knife level quick when used on abrasive matters like cardboard for example.

S90V eats brown cardboard for breakfast and it stays sharp for very long but is it tedious to put it back to a crispy razor edge.

That’s great when you need long lasting working knife on a trip when you have not planned to bring a sharpening stone for example and Sal trusts enough S90V to put that very alloy on all his own special Sprint Runs with CF Handle. I have never been disappointed by S90V and even on fixed blades or on the Manny folders it has always been a game changer in term of long lasting sharpness and is even better than CPM100V in my book.

S90V is also very stainless. Unless you want to use your knife in the ocean, it can handle some hard work in the forest without to be cleaned immediately.

It has been found that this S90V Urban got a little thinner blade 0.23 cm against 0.29 cm… The blade is also a little shorter than previous Urban bot nothing I have noticed in terms of utility.

This Urban has been made in Italy and in my own experience Maniago craftmanship has never been a bad surprise. Your mileage may vary but this is mine. I have been happy with my Spytalians !

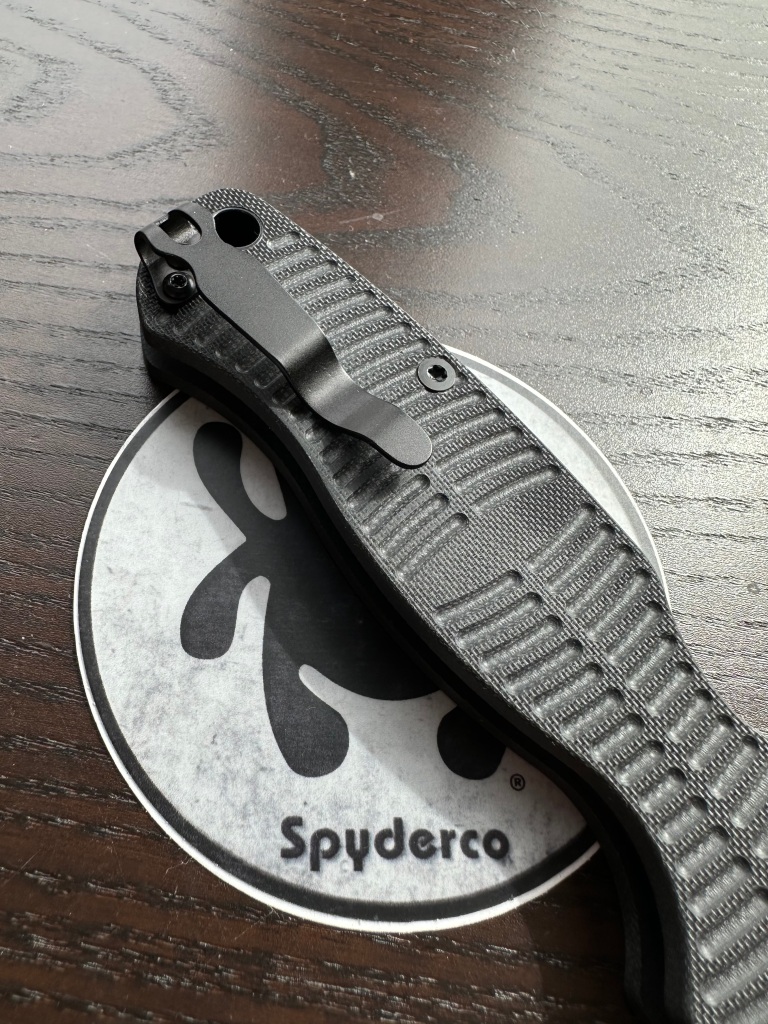

G10 is not a current material on Urbans as FRN is everywhere and, better, the texture of this G10 is even more unique. I was first thinking to turned this knife into a pebble but, naah ! It is great as it is.

I have just adjust the feel by sanding it but all in all this is great high quality made handle and again kuddos to Maniago.

All Heinnie Haynes exclusive got that red treatement on the handle, this is their signature. And a G10 version got a longer steel backspace on the handle closing it.

Now about the action, this Urban has been the most hard to close of all my splipjoints ! It is really a positive point. I can still open it with quick movement of my wrist but the closing ask for some force which is really rare (even in Spyderco production, the first UKPK were chewing gums to quote Guillaume, Spyderco Fan Club moderator).

Strong spring, and no lock make it a great candidate for carrying a legal folder nowadays.

Now about geometry, Maniago desserves another kuddos ! As you can see on the picture above, I was able to split a bottle butt in a single pass with the factory edge. This is also rare ! Even my lovely Hellboy needed some thinning before to reach that level. This is thin geometry right out of the box !!

The short blade drop point makes it a great whittler and Spyderco knows how to make little big knife. The hump and the choil are transmitting your force’s cuts directly to the blade, sparing the handle, its axis and its mechanism. This is clever and Sal has been inspired by San Francisco Gambler’s knives. His first implementation of this “cockpit” has been 30 years ago on the C36 military. So choils/humps binome are clever and great for avoiding a non locking blade to close on your finger. This is a must have !

So here we got a legal folder with a non threatening blade, strong non locking spring, great geometry and stellar particule metallurgy steel.

What not to love in this wonderful Urban ?

You can cut a pizza in your plate and use it as a steak knife without raising any eyebrows. I use my knives in plates and I know how to avoid to get them dull on the plate ceramic. My mother in law is never putting a knife near my plate, this is how I can spot where I’m going to sit on her table eventually.

Also the Urban got the perfect size to be carry in A 501 watchpocket, and as you can see mine has been shredded by many aggressive G10 handles before massive sanding.

So I highly recommend this great exclusive little knife, again it is not cheap but quality is there from the tip to the clip.