I’ve been tenacious — truly tenacious — in resisting the C122 Tenacious, even though I’d had my eye on that folder since 2008. After 17 years of flirtation, I finally ordered one. Why the delay? Its main weakness was always the less-than-stellar steel compared to the high-end knives I already owned.

Now, the CPM-M4 version is here to quench that long-standing thirst.

I don’t have much memory of a CPM-M4 serrated edge, except with another Eric Glesser design: the Dodo Exclusivefrom Blade HQ (C80GM4S). The Dodo was a real wood slasher — its S-shaped blade trimmed vines deeper and faster than almost any other, and the comfortable handle was perfect for power cuts.

Opportunities to play with a serrated CPM-M4 edge have been rare — until now. Here it is.

Back in 2008, when the Tenacious have been released it was a success.

Eric Glesser’s design was appealing to many for a simple reason: it was a well-thought-out, tough workhorse knifeavailable for around €30 (or less). A true blue-collar tool — built to be used and abused, like a modern-day Buck 110 for the pocket.

The best thing about the Tenacious was that it offered a thick, sturdy, well-built liner lock at a time when liner locks were falling out of fashion. Easy to display, easy to use, this no-choil, long-edge, compact working folder from Eric Glesser was a hit — and one of the best ways to catch the Spydervirus.

Now there is a FRN version in CPM S35VN. But it is as heavy as the G10 version and I’m not really a fan of FRN… Even if I absolutely love the FRN scales of my Serrated Chaparral.

I remember Bushcrafters being the first to sing the praises of the Tenacious. An example:

“I’ve thrown it, dropped it, batoned wood as thick as my wrist, chipped the edge multiple times (didn’t think 8cr13mov could chip, thought it was too soft but was wrong), I’ve left in outside ONCE in the rain overnight because I forgot I placed it on my front porch the previous day, I have spine whacked it (just don’t, I most likely have an impulse problem… lol … same problem that causes me to buy a lot of knives) I’ve dug holes, stabbed the ground to cut weed roots out, and much much more...

I think by now you get the point. I treated the tenacious as if I got it for free and had 1000 more to replace it if something happened. I treated this knife as if I hated it.

The result? 4 years later, the Tenacious opens smoother than it ever has, not a speck of rust since I purchased it, I have oiled the blade a couple times but I can guarantee it was less than 20 times total in the last 4 years, lockup is a bit less solid, BARELY any blade play from side to side, even less blade play from front to back, g10 scales look smoothed over and scarred, but to be honest there is still plenty of traction.

All in all, this knife is much more than what most of you need from a folder.”

My Persistence experience was excellent as described in my 2012 review (green words lead to link) but eventually I was disappointed with their steel. 8Cr13MoV can get sharp but lose sharpness much too fast for my uses. It was frustratring. I still got 8Cr13MoV knives like the Clipitool which is a great oyster knife. 8Cr13MoV is tough for a stainless steel, no surprise it was chosen for the Tenacious line.

The Tenacious is a sturdy well made liner lock folder with a super tool steel blade.

“This remarkable expression of the Tenacious® elevates this best-selling design to all-new heights with a blade crafted from American-made CPM M4 tool steel. Produced by the particle metallurgy process, CPM M4’s sophisticated alloy composition, high vanadium content, and extremely fine grain structure give it exceptional wear resistance and toughness-properties that translate to outstanding edge retention and impact resistance in knife blades. This knife’s full-flat-ground blade is available in both PlainEdge™ and CombinationEdge™ formats and is housed in a handle featuring brown peel-ply-textured G-10 scales.“

I have written many reviews about that fabulous alloy CPM-M4 it has never disappointed me and since I have sold my CPM-M4 Military and kept my Yojimbo 2 and Mantra 2 (reviewed and sharpened by JD) and use them hard, I know it is reliable and get a nice patina.

A lil’oil will prevent rust. CPM M4 is not 52100 and the patina will come slowly after cutting some lemons…

“CPM M4 has good edge holding, sharpening ease, toughness, strength, and is not a rust monster…” to quote Rangodash.

Now a blade is 1/3 steel, 1/3 Heat Treatment and 1/3 geometry.

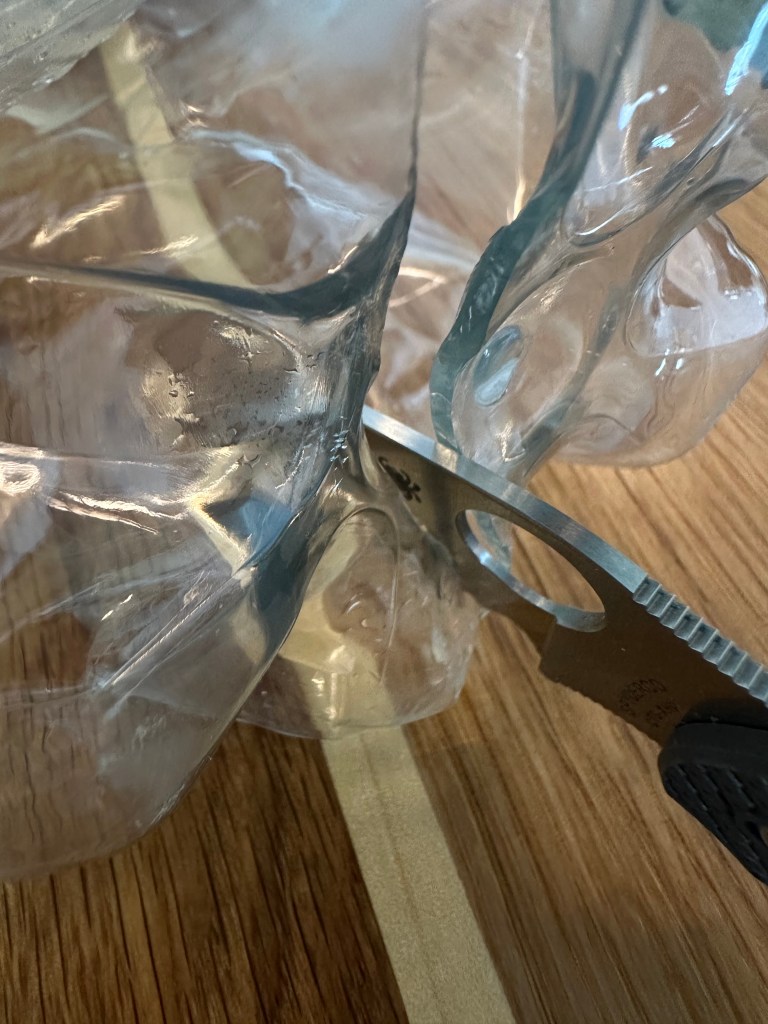

The Coke butt bottle pushing cutting test has been done with the factory edge right out of the box. It is thin behind the edge. It’s a good blade thickness for more nuanced jobs, but there is added strength from the thicker spine.

The knife sliced right in the middle were the materiel is thicker.

This is just outstanding !

There are a great geometry and a thin edge on that tough CPM-M4 blade. The result is a sturdy matter separator.

It is not an exploit to cut into some tin can but the same “shallow”, “non snaggy” kind of serrations as the Chaparral made it easy.

Again, this is a “performance oriented” knife. The blade is not too thick like some “tactical” toys. It is made to perform not to show off.

“For notching, serrated edges work great. Feathersticking, maybe, maybe not. Serrated edges are ground on the show side, so they actually work better when used left-handed for cuts like that. I carry a serrated K390 Police4 all the time for rough work. It goes through little volunteer elm trees like a chainsaw. A SharpMaker makes it a breeze to maintain the edge.” to quote Yablanowitz.

The liner lock is thick in the same spirit of Gayle Bradley’s folders.

The knife opens with a loud KLAK! — no blade play in any direction. The detent is strong but slightly “elastic,” meaning the blade moves a little before the release/tipping point engages. This makes it very secure, with no risk of accidental opening. I’ve noticed the same elasticity on the titanium version of the Tenacious. It’s important to note: this is not a weak detent — the blade won’t open without a deliberate, serious force.

Using the knife in Spyderdrop mode, a flick of the wrist catches the blade in the Spyderhole with no issue. Closing remains perfectly secure. There’s a tiny squeak out of the box, but a few drops of nano oil should mute it. The action isn’t buttery smooth like a compression lock on ball bearings, but after a bit of breaking-in and running-in, it will be wonderful.

The solid clip is delivered mounted in Tip Down carry, which suits well this knife for the Spyderco Drop featured on the Military 1 which got the same kind of “around the pivot” clip.

I have no intention of using tip-up carry or a deep-carry clip. This knife is a tool, meant for easy access rather than a stealthy edge. The Tenacious is always noticeable in the pocket, but that sturdy clip guarantees quick availability — reminding me of Massad Ayoob’s teachings.

Spyderdropping is an extremely fast way to get the blade into action — faster than many switchblades. Sal Glesser was already demonstrating this skill almost 30 years ago: grab the knife by the Spyderhole and SCHLAK! — it’s open and ready to cut.

The Tenacious features full steel liners, unlike the nested liners on the Military line. There are no backspacers, making it easy to clean under running water. At 120 grams, it’s not a lightweight folder — I appreciate a bit of heft on a working tool. (For reference, the new titanium version is 93 grams.)

Notice how perfectly centered the blade is right out of the box. The quality control on this “made in China” folder is impressively high.

(Sal’s Titanium Catbird (only 200 were made) next to Eric’s Tenacious.)

Eric and Sal have taken their time with the Byrd Line and their budget line to get the best from a family of makers in China. The Glessers have moved slowly but steadily, developing a trustworthy and excellent relationship with the knifemakers there.

To quote JustinRose40 on the forums in 2011:

“Yes, every time I show someone my Tenacious I have to say “well it’s made in China but it’s not a China Knife, it’s still a Spyderco”. To which they usually say something like, “yeah I could tell that as soon as you handed to me”.

Since 2011, China has made huge leaps in knife manufacturing quality, and this steady improvement is clearly noticeable in the “new” rendition of the venerable Tenacious.

On Eric’s designs, there’s sometimes no choil, but you can notice a clever feature: a “proto-flipper” that acts as a quillon or guard to protect your fingers in case the lock ever failed.

Since 2008, I haven’t heard of any critical lock failures on the Tenacious or the larger Resilience. The Tenacious has earned its legendary status for a reason.

Another Eric design with an excellent blade-to-handle ratio is the Mantra 2, which uses a flipper. (I’m not a fan of that little opening hole — dirt always collects there!) Still, it’s a great design. The Mantra 1, with an opening hole, feels like the Taichung-made “uncle” of the M4 Tenacious.

The peel-ply-textured G10 scales don’t need sanding; they’re well balanced and won’t shred pockets. The brown color makes it feel less threatening, in my book.

Let’s put it to use while the satin blade is still silver.

The knife bites into wood like no tomorrow. The serrated CPM-M4 edge is a joy to use — it goes deep and steady, putting a smile on my face every time.

Blast from the past: the last combo-edge/semi-serrated knife I used was over 20 years ago — a Pre-Production D2 AFCK. As you can see, it’s been heavily used, and its geometry, steel, and blade-to-handle ratio aren’t nearly as refined as the Tenacious.

That macro shot shows the very smooth way to go from chisel ground serrations to plain edge.

“Serrated edges aren’t for everyone, and you may not like them, but you’ve got to get at least one just to try! Keep it around for nasty work, wet abrasive rope, zip-ties, yardwork, or playtime like in the pool, or at the lake or beach. Not to mention fishing duties.” to quote Benben.

The difference in cutting efficiency between a saber grind and a full flat grind is obvious. I don’t need to tiptoe around it — the advantage is clear.

Now let’s compare the Tenacious with various folders and fixed blades.

The Tenacious got a better blade/handle ratio than the Paramilitary 2 and a longer blade for a shorter handle. This is one key of the success of that design.

Almost the same length as the Chief.

No choil on the Wolfspyder too.

Since I play with Bushcraft here a nice combo to go in the wood. The Proficient is a masterpiece.

And with the ultra solide Boker in Magnacut. The 8,6 centimeter long blade of the Tenacious is generous edge wise.

Of course, I’ll strop that partially serrated blade on leather — no fear at all. I have my method for serrations, using the corner of the leather pad.

Maintaining the combo edge won’t be an issue; I’ll keep it sharp with cornered ceramic and jade stones.

So what do you get for €139 — the price I paid at the Coutellerie Champenoise? I’m really happy with my purchase. I plan to use the Tenacious a lot and on anything, simply for the pleasure of testing it on various materials. This knife isn’t afraid of plastic, wood, food, bones, cardboard, or aluminum.

This CPM-M4 version is set to show the full potential of one of the beefier EDC knives, especially with its serrated half-edge carved from super tool steel. Over 17 years, the Tenacious has proven it can withstand a lot of abuse.

The CPM-M4 Tenacious is not only a workhorse but a warhorse, like the pictured Adamas. I can easily imagine any soldier being glad to have such a reliable knife at this budget.

It’s slightly larger than small pocket knives, but smaller than the oversized ones some carry just to show off. The Tenacious would make an excellent day-hiking knife — a folder ready for the great outdoors. I’d take it on a trip to Africa or on a photo safari in the natural parks of Tuscany.

(this will often dull the blade’s edge with a little shining spot. Not here… Thanks to the serrations again ! )

This CPM-M4 Tenacious is sold at roughly double the price of the standard version, but in my opinion, it’s a rare chance to have this alloy on that knife. CPM-M4 pushes the boundaries of reliability and is a real pleasure to keep razor-sharp.

CPM-M4 will not chip and stays sharp for long. It’s a steel that has been used in cutting competitions. While Tuff Glideand various oils can keep it spotless, I prefer the protection of a gentle natural patina.

For twice the price of the vanilla Tenacious, this upgraded version delivers another level of performance in terms of toughness and edge retention.

“Old school cool with the Walker lock and satin finish. Well done Eric Glesser!” to quote Clay H on the Forums.

My brown Tenacious looks gorgeous in its “beautility”, practically begging to be used across all terrains — sand, rain, or more. All in all, this beater is a beefed-up workhorse, built to be used hard and carried proudly.

The knife snuggles perfectly inside the pouch you can pass in a belt.

The knife snuggles perfectly inside the pouch you can pass in a belt.